Choosing the Best Waterproof Automotive Electrical Connectors A Comprehensive Comparison

Table of Contents

- Understanding the Importance of Waterproof Automotive Electrical Connectors in Harsh Environments

- Key Features to Look for in Waterproof Connectors: Ratings and Standards Explained

- Comparative Analysis of Material Types: Plastic vs. Metal in Connector Durability

- Evaluating Seal Technologies: How IP Ratings Impact Connector Performance

- Cost-Benefit Assessment: Balancing Quality and Affordability in Connector Selection

- Industry Case Studies: Successful Applications of Waterproof Connectors in Automotive Engineering

- Enhancing Vehicle Durability: The Importance of Pin Male Waterproof Automotive Electrical Connectors 7122-3010

- FAQS

- Conclusion

- Related Posts

When it comes to the automotive world, you really can’t underestimate how important reliable connections are — especially those waterproof electrical connectors. I mean, if you look at the latest reports from MarketsandMarkets, the global market for automotive connectors is expected to hit around $30 billion by 2025. And waterproof connectors? They’re a big deal because they help keep vehicles running smoothly, no matter what the weather throws at them.

Yueqing Haidie Electric Co., Ltd. has really made a name for itself in this space, focusing on high-quality wire harnesses that meet the needs of all kinds of automotive parts. With years of experience behind us, we've gained a lot of trust from our customers, and our reputation’s only grown. As we get into this comparison of waterproof automotive electrical connectors, our goal is to give manufacturers and suppliers the info they need to pick the right products — products that last and keep things running flawlessly, no matter the environment.

Understanding the Importance of Waterproof Automotive Electrical Connectors in Harsh Environments

In today’s automotive world, waterproof electrical connectors are more important than ever. With cars constantly facing tough conditions — from heavy rainstorms to sizzling heat — making sure those electrical connections stay reliable is a big deal. Did you know that, according to Allied Market Research, the global market for automotive connectors is expected to hit around $29.74 billion by 2025? And a big part of that growth comes from waterproof connectors, which really boost how durable and reliable these parts are.

Waterproof connectors are built tough to handle all the environmental stressors out there, helping them last longer and perform better. For example, using high-quality materials like polyamide and silicone can seriously cut down the chances of failure when exposed to water. In fact, a survey by the Society of Automotive Engineers found that vehicles with solid waterproof connectors see about 30% fewer electrical problems in tough conditions compared to those without. That’s a big deal for overall safety and peace of mind. As the auto industry keeps pushing forward with new innovations, making sure waterproof connectors are part of the plan is key for manufacturers who want to keep up, improve vehicle performance, and make customers happier — even when the going gets rough.

Choosing the Best Waterproof Automotive Electrical Connectors

| Connector Type | Waterproof Rating | Temperature Range | Material | Typical Applications |

|---|---|---|---|---|

| Sealed Connector | IP68 | -40°C to 105°C | Polyamide | Automotive, Marine |

| Molex Connector | IP67 | -20°C to 85°C | Thermoplastic | Industrial Equipment |

| Deutsch Connector | IP69K | -55°C to 125°C | Polycarbonate | Heavy Equipment |

| Circular Connector | IP67 | -40°C to 90°C | Aluminum Alloy | Aerospace, Automotive |

| Blade Connector | IP67 | -40°C to 125°C | Nylon | Automotive Wiring Harnesses |

Key Features to Look for in Waterproof Connectors: Ratings and Standards Explained

When you're on the lookout for waterproof electrical connectors for cars, it's really important to get a good grip on what features make them reliable and long-lasting. For starters, one of the main things to look at is the IP rating—that’s basically how well the connector can keep out dust and water. The higher the number, the better it protects. If you’re dealing with tough conditions or wet environments, connectors with an IP67 or even IP68 rating are usually your best bet—they can handle being submerged in water and still perform like champs.

Another thing to keep in mind is what these connectors are made of. Top-notch ones are often crafted from sturdy materials like nylon or thermoplastic elastomers (TPE). These materials hold up pretty well against changing temperatures, UV rays, and chemicals—pretty much everything Mother Nature throws at them. Plus, features like O-rings or grommets really boost their waterproof abilities. When all these elements come together, you end up with a secure, durable connection that can handle the rough conditions cars sometimes face. Trust me, paying attention to these details makes a huge difference in your setup’s longevity and performance.

Comparative Analysis of Material Types: Plastic vs. Metal in Connector Durability

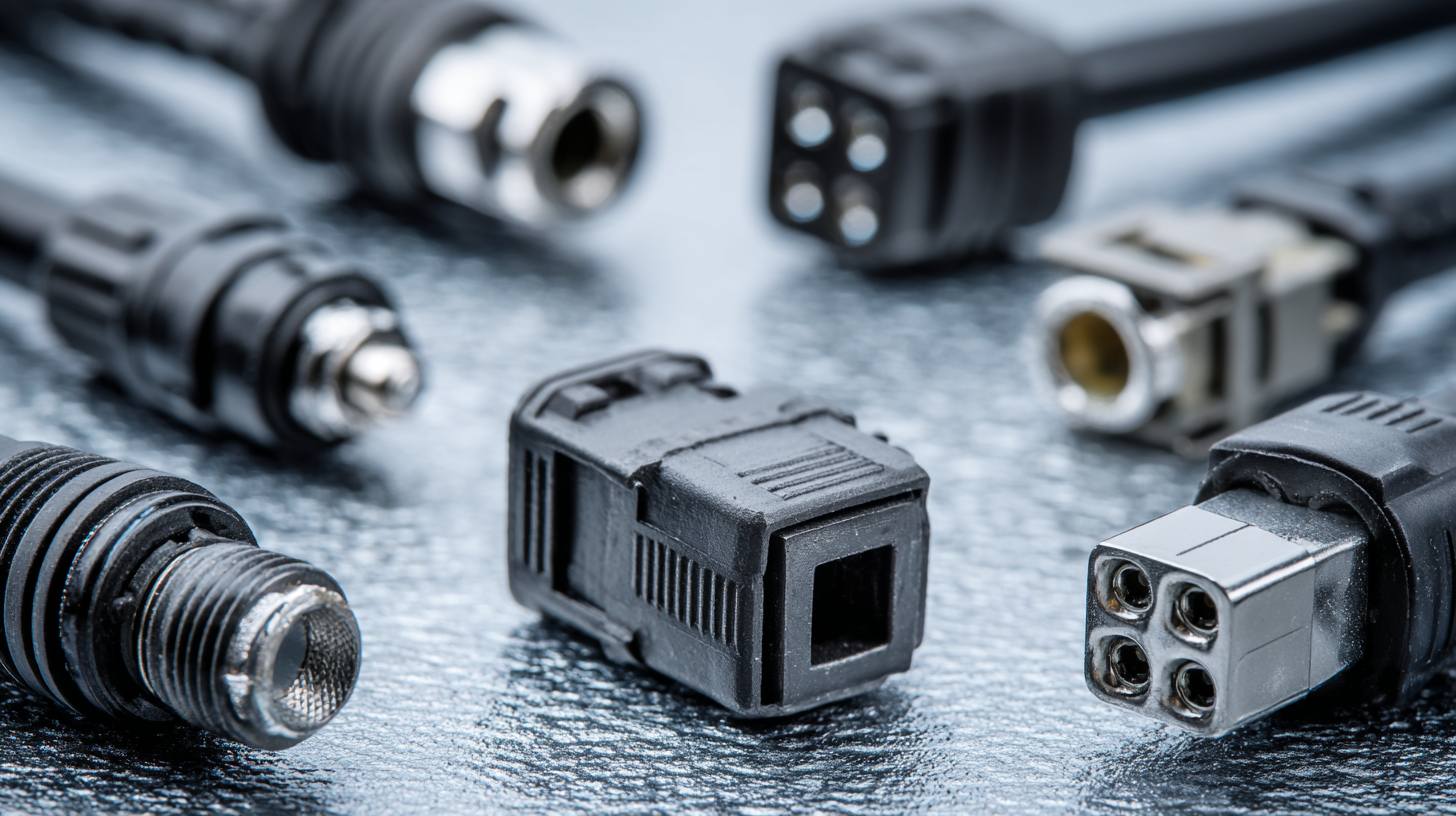

When you're on the hunt for the best waterproof automotive electrical connectors, one of the biggest things to think about is what material they're made from. If you compare plastic and metal connectors, you'll see some pretty important differences in how durable they are and how well they fit into automotive uses.

Plastic connectors tend to be lighter and don’t rust easily, which is great, but they can struggle in really extreme temperatures or when facing lots of mechanical stress. Metal connectors, on the other hand, usually handle these tougher conditions much better—they’re stronger and last longer. The catch? They can be more prone to rust if they're not properly coated.

Lately, market forecasts show the auto fasteners industry is expected to grow quite a bit—from around $24 billion in 2024 to over $37 billion by 2032, with an average annual growth rate of about 5.5%. As folks look for more reliable and long-lasting electrical systems, picking the right connector material becomes super important to ensure everything works smoothly and stands the test of time.

Quick tip: When you're choosing connectors, think about where they'll be used. If it’s a place with a lot of moisture or a salty, corrosive environment, metal options might actually last longer. Also, don’t forget to check out the manufacturer’s specs — go for connectors that meet industry safety and performance standards to keep things running safely and reliably.

Evaluating Seal Technologies: How IP Ratings Impact Connector Performance

When you're picking out waterproof electrical connectors for your car, it’s pretty important to get a good grip on how the seal tech works and what it means for the connector’s performance. You’ve probably heard about the Ingress Protection — or IP — ratings, right? Those ratings are like the industry’s way of telling you how well a connector can handle dust and water. For example, if a connector is rated IP67, it can handle being briefly soaked in water, like maybe a quick splash. But if it’s IP68, it’s tough enough to stay submerged for longer periods — pretty serious stuff. A report from the Society of Automotive Engineers, or SAE, mentions that choosing connectors with higher IP ratings doesn’t just boost reliability — it can also save you dollar signs down the road, potentially cutting maintenance costs by up to 30% over time.

When you’re checking out connectors, think about where they’re going to end up. If it’s an environment with crazy temps or lots of vibrations, then you really want something with solid sealing. Materials like silicone or fluoropolymer are your friends here — they’re super durable and stand up well against nasty chemicals.

Pro tip: Don’t just assume the specs are right — always double-check the manufacturer’s info to make sure the connector’s IP rating matches what you need for your project.

Yes, higher-rated connectors can feel a bit pricier upfront, but trust me, they often pay off in the long run since they tend to fail less and last longer.

Another tip: Take some time to really analyze your project’s needs. Think about what kind of performance you expect under pressure and whether the connector will play nice with other parts in your setup.

Cost-Benefit Assessment: Balancing Quality and Affordability in Connector Selection

When you're choosing waterproof connectors for your car's electrical system, it’s really all about finding that sweet spot between quality and affordability. There are tons of options out there from different manufacturers, each with their own price tags, performance levels, and durability. Taking some time to weigh the costs against the benefits can really help you figure out which connectors will actually do the job without breaking the bank.

Investing a bit more in good-quality connectors pays off in the long run, since they tend to resist harsh weather conditions better and last much longer, saving you headaches down the line.

That said, keep in mind that top-tier connectors usually come with a higher upfront cost. So, it’s worth thinking about how often you might end up replacing cheaper, lower-quality options — whether because they wear out or get corroded. By comparing the initial expense with the long-term reliability and performance, you can make smarter choices that will save you money and hassle later on. Ultimately, it’s about finding that right balance—where quality and price meet—to keep your electrical connections solid and dependable, no matter what kind of conditions come your way.

Industry Case Studies: Successful Applications of Waterproof Connectors in Automotive Engineering

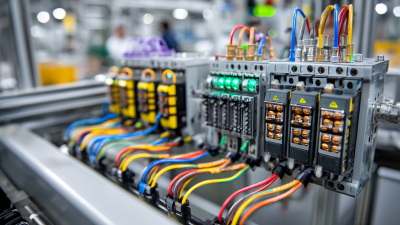

In the automotive world, folks really value dependable and long-lasting parts—especially when it comes to electrical connectors that have to stand up to tough conditions. Waterproof connectors for cars have shown up in all kinds of real-world examples, proving just how important they are for keeping vehicles running smoothly and lasting longer. Take off-road vehicles, for instance—these connectors are a lifesaver because they stop dirt and water from sneaking in and messing with the electrical system. When manufacturers switch to waterproof connectors, they often see a noticeable boost in reliability, and happy customers are the result.

And then there’s electric vehicles (EVs). Using waterproof connectors there is a big deal because it keeps high-voltage parts safe and working efficiently. With EVs becoming more common, it’s super important that these connectors can handle water exposure without any issues. Engineers have shared stories about how waterproof connectors have made it possible to design batteries that stay protected, even in crazy weather. These advances are paving the way for cars that are not just more durable but also more reliable. All in all, picking the right electrical connectors makes a huge difference in how well these vehicles perform—and that’s a fact worth noting.

Enhancing Vehicle Durability: The Importance of Pin Male Waterproof Automotive Electrical Connectors 7122-3010

In the pursuit of automotive excellence, vehicle durability is paramount, significantly impacted by the quality of electrical connectors used in manufacturing. The pin male waterproof automotive electrical connector 7122-3010 exemplifies the advancements in technology aimed at enhancing vehicle resilience. As vehicles increasingly face demanding conditions, ensuring that electrical connectors are robust and waterproof becomes crucial. According to a recent industry report, approximately 70% of automotive failures are attributed to electrical malfunctions, underscoring the need for reliable components.

The 7122-3010 connector, part of the 7.8 series, is specifically designed to withstand harsh environments, with its waterproof feature protecting against dust and moisture. This adds an extra layer of durability that is critical for automotive applications. Research indicates that connectors that meet high standards of waterproofing can extend the lifespan of electrical systems by up to 30%, significantly reducing maintenance costs for manufacturers and consumers alike. As vehicles become more equipped with advanced technology, like electric and hybrid systems, the demand for high-quality connectors like the 7122-3010 grows correspondingly.

Manufacturers looking to enhance their vehicle durability should prioritize components that offer superior protection against environmental factors. The 7122-3010 connector stands out with its design and capability, promising not just compliance with industry standards but also an enhancement in overall vehicle performance and safety. By investing in high-quality waterproof connectors, manufacturers can ensure greater reliability and longevity in their products, solidifying their reputation in an increasingly competitive automotive market.

FAQS

: Plastic connectors are lightweight and corrosion-resistant but can struggle in extreme temperatures and mechanical stress. Metal connectors offer superior strength and long-term reliability in harsher environments but may be prone to corrosion without proper coatings.

The automotive fasteners market is projected to grow from $24.08 billion in 2024 to $37.11 billion by 2032, with a compound annual growth rate (CAGR) of 5.55%.

For applications exposed to high moisture or corrosive elements, metal connectors typically provide better longevity, while plastic connectors may be suitable for less demanding conditions.

The IP rating system categorizes connectors based on their levels of dust and water resistance, which is crucial for ensuring reliability in various environmental conditions.

Connectors rated IP67 can withstand temporary immersion in water, while those with an IP68 rating can tolerate continuous submersion.

Connectors meeting higher IP standards enhance reliability and can reduce maintenance costs by up to 30% over time due to lower failure rates.

Materials like silicone or fluoropolymer are recommended for their durability and resistance to harsh chemicals in automotive applications.

Reviewing manufacturer specifications ensures that the connectors meet specific requirements for safety, performance, and compatibility with environmental conditions.

While higher-rated connectors may have a higher upfront cost, they often lead to long-term savings due to extended lifecycles and lower failure rates.

Conduct a thorough analysis of the application’s requirements, considering factors like performance under pressure and compatibility with other components.

Conclusion

You really can't underestimate how important waterproof automotive electrical connectors are these days, especially in tough environments where moisture and dirt can wreak havoc on vehicle performance. When you're choosing these connectors, there's a lot to consider — like technical ratings and standards — so it helps to have a clear idea of what features matter most. For instance, comparing materials such as plastic and metal sheds light on their durability, while looking at seal tech and IP ratings shows how these factors impact dependability and performance.

And let's not forget about cost. Finding that sweet spot between quality and budget is key, especially for manufacturers trying to get the most bang for their buck. We've also looked into real-world examples from the industry, showing how waterproof connectors are making a real difference in vehicle efficiency and reliability. Here at Yueqing Haidie Electric Co., Ltd., we're all about offering top-notch wire harness solutions that match these standards — it's what makes us proud to be a trusted partner in creating dependable automotive electrical connectors.

Related Posts

-

Ultimate Guide to Comparing the Top Automotive Plug Connectors on the Market

-

Top Quality Vehicle Wiring Connectors from a Leading Chinese Manufacturer

-

5 Reasons Why Board To Wire Connections Drive 30 Percent More Efficiency in Industrial Applications

-

Comprehensive Guide to Best Wire Connecters with Technical Specifications and Installation Tips

-

Understanding the Common Challenges in Automotive Wire Terminals and Connectors

-

7 Proven Benefits of Choosing the Best Connector Housing for Your Needs

Blog Tags: