5 Reasons Why Board To Wire Connections Drive 30 Percent More Efficiency in Industrial Applications

Table of Contents

- Benefits of Board To Wire Connections in Industrial Settings

- Enhanced Energy Efficiency: An In-Depth Comparison

- Reducing Installation Time with Board To Wire Solutions

- Minimizing Maintenance Costs: Board To Wire vs. Traditional Methods

- Improved Reliability: How Board To Wire Connections Outperform Alternatives

- Flexibility and Scalability: Adapting Board To Wire for Changing Needs

- Exploring the Advantages of the 36 PIN MALE 68145-3615 Automotive Connector for Reliable PCB Connections

- FAQS

- Conclusion

- Related Posts

In today’s fast-moving industrial world, squeezing out every bit of efficiency is more important than ever. One cool development that’s been gaining traction is the Board To Wire connection. Industry studies actually show it can boost efficiency by up to 30% in many different contexts. What’s great about these connections? They cut down installation time significantly and make things more reliable — a real win, especially for sectors that need high-performance wiring. At Yueqing Haidie Electric Co., Ltd., we get how crucial these kinds of advancements are. We’re all about providing top-notch wire harness solutions for automotive and industrial uses, and our dedication hasn’t gone unnoticed. As more industries move toward smarter, faster setups, switching to efficient wiring options like Board To Wire is pretty much essential if you want to stay ahead of the game. We’re proud to help our customers navigate this shift and succeed.

Benefits of Board To Wire Connections in Industrial Settings

You know, board-to-wire connections are really starting to get recognized more and more in industrial settings, and for good reason.

They offer a pretty simple and efficient way to connect various components inside complex systems.

Honestly, because they're so straightforward, they cut down on assembly time and lower the chances of making mistakes—which can really boost productivity, sometimes by around 30%.

That kind of efficiency is a game-changer, especially for industries trying to push out more while keeping quality high.

One thing I find pretty cool about these connections is how much space and weight they save.

That means you can make better use of the limited room inside machines or gadgets. Plus, with fewer connection points, there's less chance something will go wrong, making the whole operation more reliable.

If you’re thinking about trying these out, a couple of tips might help.

First, make sure everything lines up properly during assembly so you don’t put extra strain on the wires—that can really help extend their life.

Regular check-ups are also a lifesaver; catching any issues early on can keep things running smoothly.

And don’t forget, getting your team trained on the latest tech related to these connections can really boost both efficiency and safety on the shop floor.

It’s all about staying in the loop, right?

Enhanced Energy Efficiency: An In-Depth Comparison

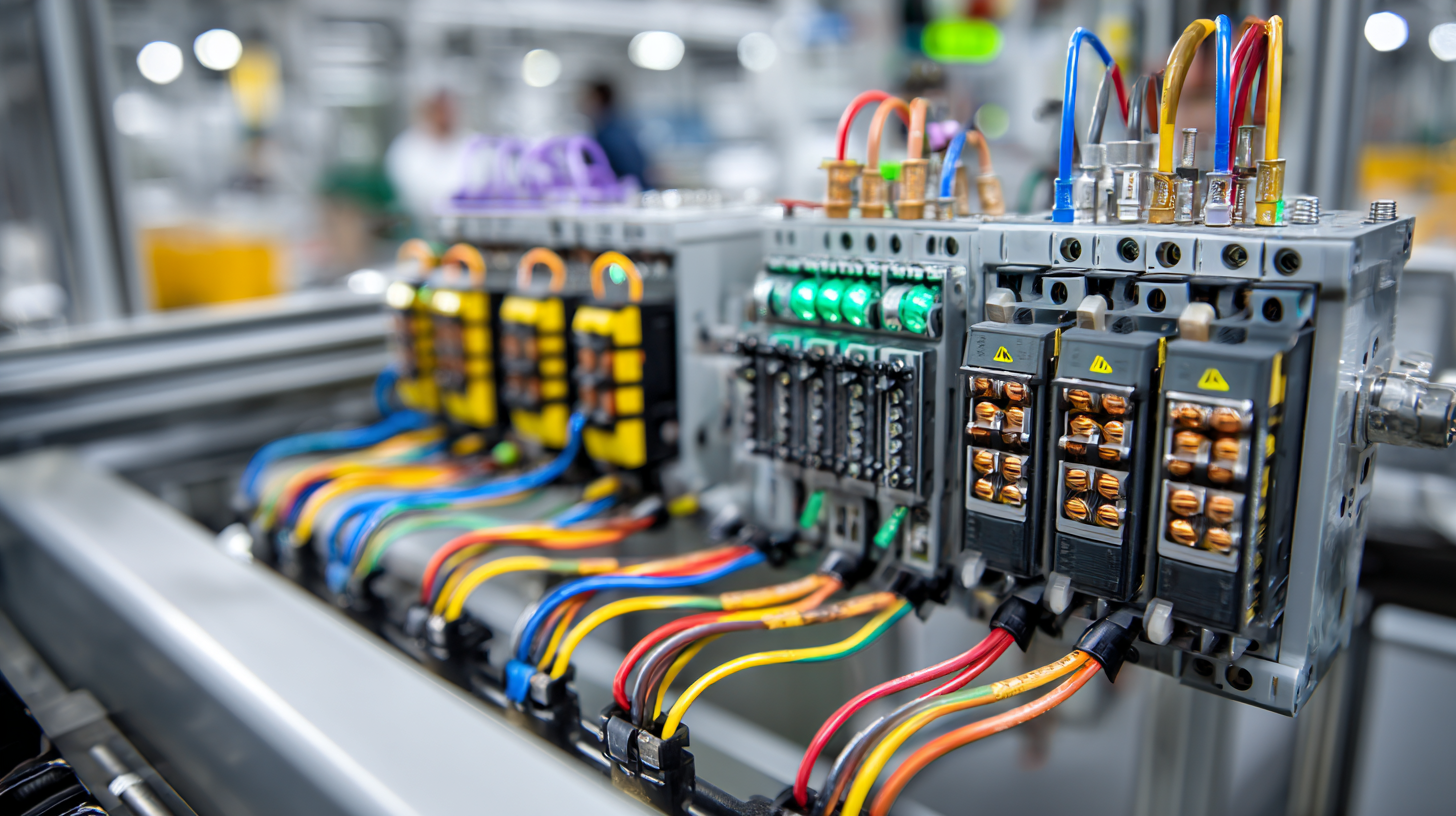

When it comes to industrial settings, you really can't underestimate how important energy efficiency is. It's not just about saving on costs, but also about keeping productivity flowing smoothly. One of the coolest innovations making waves here is the board-to-wire connection. It allows for more direct power delivery, which means less energy slips away compared to those old-school wiring methods we used to rely on. Plus, this simpler setup helps keep things cooler and cuts down on energy use, all while extending the lifespan of your gear.

Here's a tip: it's a good idea to give your board-to-wire connections a quick check every now and then. Make sure they're nice and tight and free of corrosion. That stuff can really mess with performance and end up costing you more energy in the long run.

And speaking of benefits, these connections also make installation way easier. You get faster setup, less waste on materials, and save some bucks on labor. That’s a win-win because it makes your manufacturing line more flexible and definitely helps in reducing energy costs.

Another tip—invest in good quality connectors built to handle the industrial grind. They’re more reliable, which means less maintenance and fewer replacements, helping you keep those energy bills in check.

All in all, switching to board-to-wire connections isn’t just about modernizing — it’s a smart move toward a more efficient and sustainable operation. Staying updated with the latest tech really can make a big difference in the long run.

Reducing Installation Time with Board To Wire Solutions

In the fast-moving world of industrial setups, getting things done efficiently really matters. Lately, board-to-wire connections are changing the game—making installations faster and easier than ever. When companies switch to these solutions, they can cut down wiring time, speed up production, and reduce downtime. It all adds up to smoother operations and, of course, some immediate cost savings.

At Yueqing Haidie Electric Co., Ltd., we're all about providing top-notch wire harnesses, especially for the automotive side of things. Our innovative board-to-wire connectors aren’t just easy to install—they’re built tough, earning us a solid reputation and a loyal customer base. Switching over to these solutions can seriously cut labor costs because there are fewer steps involved in the assembly.

Quick tip: When you’re thinking about board-to-wire connections, make sure they’re compatible with your current systems—that way, you get the most out of them. Also, investing some time in training your team really pays off—helps them understand how these connections work and their benefits. Embracing these practices can really boost your production capacity and the quality of your output.

Minimizing Maintenance Costs: Board To Wire vs. Traditional Methods

In today’s industrial world, companies are really focused on boosting how efficiently they run things while keeping maintenance costs low — it’s all about staying ahead of the competition. One cool thing that’s been gaining traction is using board-to-wire connections instead of traditional wiring methods. These systems can actually boost efficiency by around 30%, which is a pretty noticeable jump. Unlike older wiring setups that tend to wear out over time, board-to-wire systems are sturdy and reliable, meaning they don’t need to be maintained as often. This is especially important in industries where even a little downtime can cost a ton of money.

At Yueqing Haidie Electric Co., Ltd., we totally get how crucial it is to have high-quality wire harnesses that fit our customers’ specific needs. We’ve got plenty of experience in the auto parts world, and people recognize us for delivering durable, efficient wiring solutions. By switching to board-to-wire connections in industrial settings, our clients aren’t just saving on maintenance—they’re also making their operations smoother and more streamlined. Moving towards these modern wiring options is definitely a smart move for businesses that want to boost productivity and stay competitive in today’s fast-paced market.

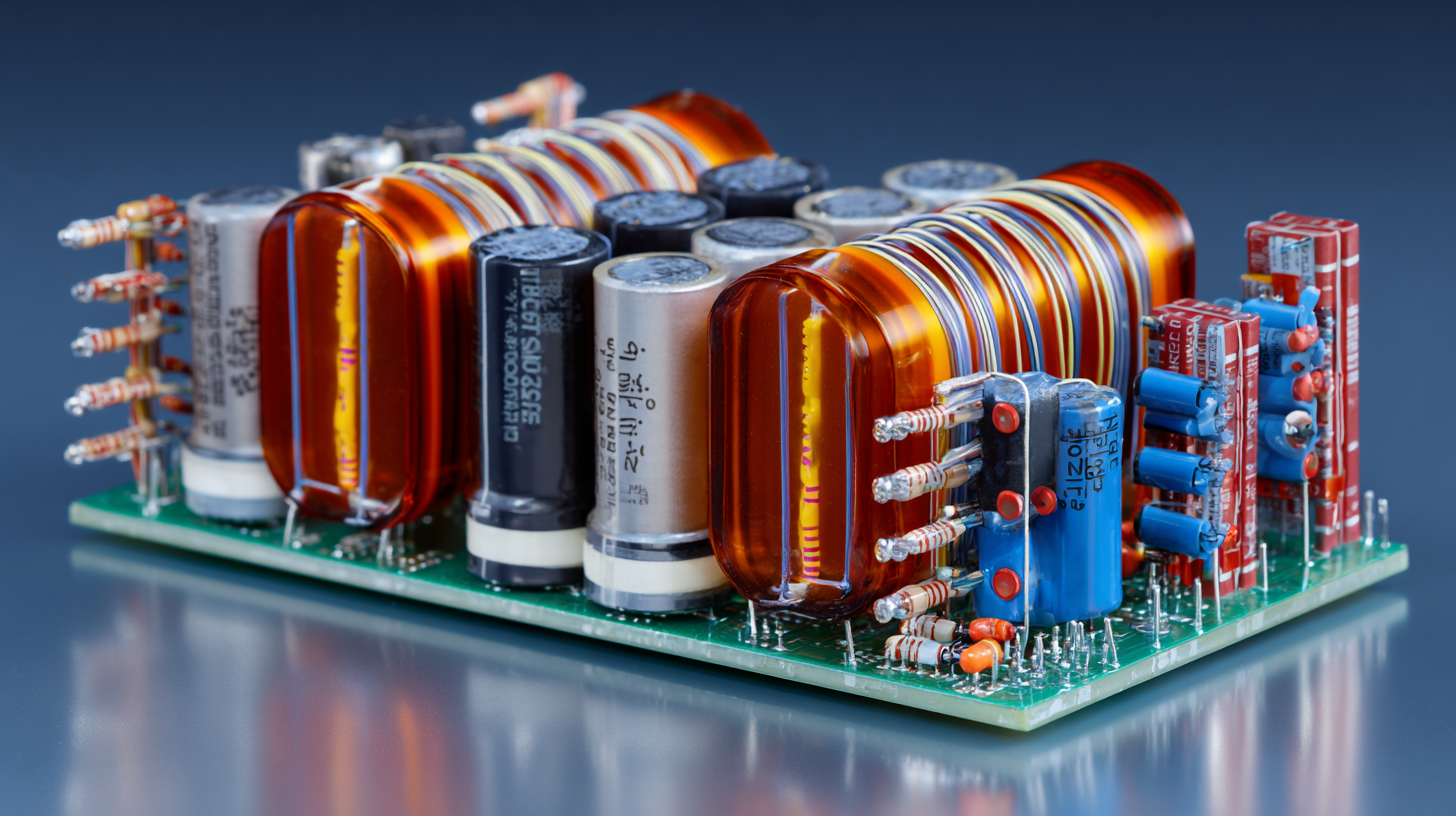

Improved Reliability: How Board To Wire Connections Outperform Alternatives

When it comes to industrial applications, reliability really is everything. That’s why board-to-wire connections have become such a popular choice—they just perform better overall. Recent research shows that these kinds of connections can actually boost system efficiency by as much as 30%, mainly because they tend to fail less often and are built tougher. Unlike the older, more traditional options, board-to-wire connections are less likely to disconnect unexpectedly, which means everything runs smoother and more reliably—especially in tough environments.

At Yueqing Haidie Electric Co., Ltd., we focus on delivering top-notch wire harness solutions, especially for the automotive industry. Our products are made to meet, and often even beat, the strictest reliability standards out there. According to some data from the International Electrotechnical Commission, systems using board-to-wire connections encounter about half as many operational hiccups compared to those with standard terminal blocks. That kind of performance isn’t just good for keeping things running smoothly; it also helps cut down on maintenance costs over time. Honestly, investing in these solid connections is a smart move for any industrial setup—really, they can make a big difference in boosting efficiency and keeping operations on track.

5 Reasons Why Board To Wire Connections Drive 30 Percent More Efficiency in Industrial Applications

This chart illustrates the key benefits of Board to Wire Connections and their impact on efficiency improvement in industrial applications. Each benefit contributes a significant percentage to overall efficiency gains.

Flexibility and Scalability: Adapting Board To Wire for Changing Needs

You know, in today's rapidly changing industrial world, being flexible and able to scale up quickly is more important than ever. That's where board-to-wire connections are really making a splash — they’re becoming a game-changer for manufacturers who need to adapt on the fly. I was reading a report from Mordor Intelligence that said the global industrial automation market is expected to jump from $200 billion in 2021 to about $325 billion by 2026. That just shows how much demand there is for systems that can be easily scaled up or down. What’s cool about these board-to-wire connections is their modular design — they let you reconfigure or expand your setup fast, meaning less downtime and more agility for your business.

On top of that, their flexibility really helps improve how smoothly operations run. A study by the International Society of Automation (ISA) shared that companies using flexible wiring solutions saw up to a 30% boost in operational efficiency. That’s probably because it simplifies installation and maintenance — no need for big, disruptive overhauls whenever you wanna make a change. As more industries jump into automation and IoT technology, I honestly think solutions like these will become even more essential, helping companies stay quick on their feet in a super competitive environment.

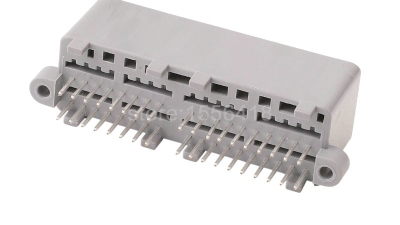

Exploring the Advantages of the 36 PIN MALE 68145-3615 Automotive Connector for Reliable PCB Connections

When it comes to ensuring reliable connections in automotive electronics, the 36 PIN MALE 68145-3615 automotive connector stands out as a top choice. Designed for robust performance, this connector excels in various applications where durability and stability are paramount. Its crimp-type design not only enhances the mechanical connection between wires but also provides a secure fit that minimizes the risk of disconnections due to vibrations and movements typical in automotive environments.

The 36 pin Auto Connecting Crimp Type Stamping Female Wire Crimp Terminal 68145-3615 complements the male connector perfectly, offering an easy-to-use solution for PCB (Printed Circuit Board) connections. This terminal is engineered for efficiency, featuring a straightforward crimping mechanism that ensures a tight and reliable attach point. Whether integrating into new designs or upgrading existing systems, this connector and terminal set collectively simplifies wiring while enhancing overall performance and reliability.

Moreover, the advantages of using the 68145-3615 series extend beyond just mechanical stability. These connectors are designed to withstand harsh environments, ensuring that your automotive components remain functional under extreme conditions. The thoughtful engineering behind this connector series guarantees that it meets the industry's high standards for safety and reliability, making it an ideal choice for automotive manufacturers and engineers looking to optimize their designs.

FAQS

: Board-to-wire connections are innovative wiring solutions that link circuit boards to wiring harnesses, designed to enhance efficiency and simplify installation processes in industrial applications.

By streamlining the wiring process and requiring fewer assembly steps, board-to-wire solutions significantly decrease the time needed for installations, leading to accelerated production timelines.

Board-to-wire connections offer a robust design that reduces wear and tear, resulting in increased efficiency (up to 30%), minimal maintenance costs, and enhanced operational reliability compared to traditional wiring methods.

Companies should ensure compatibility with existing systems and provide proper training for their teams to fully understand the benefits and functionalities of board-to-wire connections.

Adopting these connections can lead to significant reductions in labor costs as they simplify the assembly process, ultimately requiring fewer man-hours for installation.

Minimizing maintenance costs is crucial as equipment downtime can lead to substantial financial losses, making efficient and reliable wiring solutions essential for maintaining productivity.

Various industries, particularly those in automotive and heavy machinery sectors, can benefit from the reliability and efficiency provided by board-to-wire connections to enhance productivity.

Yueqing Haidie Electric Co., Ltd. specializes in high-quality wire harness solutions tailored for the automotive industry, ensuring robust performance and offering extensive experience in durable and efficient wiring technologies.

Companies that adopt board-to-wire solutions can experience immediate cost savings from reduced labor and maintenance costs, as well as improved operational efficiency.

Embracing modern wiring technologies like board-to-wire connections can significantly elevate production capacity and quality by enhancing efficiency and reducing the complexity of wiring processes.

Conclusion

Hey, have you heard about Board To Wire connections? Nowadays, they're really making waves in industrial settings because they can boost overall efficiency by up to 30%. Honestly, businesses that switch to these often see some pretty great perks — like better energy efficiency thanks to improved power distribution, faster installation times, and lower maintenance costs compared to the old-school wiring methods. Plus, these connections are super reliable, outlasting other systems and keeping things running smoothly over time.

What’s also cool is how flexible and scalable Board To Wire solutions are. They’re perfect for industries that are constantly evolving and need adaptable solutions on the fly. At Yueqing Haidie Electric Co., Ltd., we’re all about crafting top-notch wire harnesses tailored to our customers’ needs — especially in the automotive world — and people seem to really appreciate our work. Honestly, adopting Board To Wire technology could honestly be a game-changer for industrial operations, making them more efficient and reliable, especially in such a competitive marketplace.

Related Posts

-

7 Best Circuit Board Wire Terminals for Optimal Performance in 2023

-

Ultimate Guide to Choosing the Best Connecting Pin for Optimal Performance in Your Industry

-

Top Quality Vehicle Wiring Connectors from a Leading Chinese Manufacturer

-

Ultimate Guide to Comparing the Top Automotive Plug Connectors on the Market

-

5 Key Benefits of Auto Wire Harness in Modern Automotive Manufacturing

-

7 Essential Tips for Choosing the Best Car Cable Connectors for Your Vehicle

Blog Tags: