Understanding the Common Challenges in Automotive Wire Terminals and Connectors

Table of Contents

- Common Issues Faced with Automotive Wire Terminals and Connectors

- Best Practices for Selecting Quality Automotive Wire Connectors

- Essential Tools for Efficient Installation and Maintenance of Wire Terminals

- Key Factors Influencing the Longevity of Automotive Connectors

- Troubleshooting: Diagnosing Connection Failures in Automotive Wiring Systems

- Maintenance Tips to Prevent Common Wiring Issues in Vehicles

- Maximizing Efficiency in Automotive Wiring: Insights on 30 Pin Auto Connectors and Terminal 2005499-8 from 2023 Industry Reports

- FAQS

- Conclusion

- Related Posts

You know, in today’s fast-changing world of cars, having reliable wire terminals and connectors is more important than ever. As vehicles get smarter with all those new electronic features, the need for top-notch wiring solutions has really shot up. I read somewhere that by 2027, the global automotive wiring harness market could hit around $69 billion — that’s pretty crazy, right? And it makes sense, especially with all the complex systems and the push towards electric vehicles. At Yueqing Haidie Electric Co., Ltd., we’re all about providing high-quality wire harness solutions that actually meet our customers’ needs, helping to boost both performance and safety. We’re proud of our reputation for quality — enough so that other brands have popped up based on what we offer. It’s really important for manufacturers to understand the common issues with wire terminals and connectors, especially with how electrified cars are becoming. Staying on top of these helps make sure everything works smoothly and lasts longer in this electrified automotive world.

Common Issues Faced with Automotive Wire Terminals and Connectors

Automotive wire terminals and connectors are pretty much the backbone of a vehicle's electrical system. If they aren’t working right, your whole ride can run into trouble. Now, one of the biggest headaches is corrosion—yeah, that nasty rust-like stuff. It can happen when moisture or other environmental factors get to them. When that happens, it not only messes with the electrical flow but can also cause system failures, leading to expensive repairs and sometimes even safety concerns.

Then there’s the issue of installation—often, problems pop up because terminals aren’t crimped correctly. This might sound small, but loose connections can cause arcing or overheating, which is definitely not what you want. Sometimes, the quality of the components isn’t great either, which means they might not stand up to the test of time. Add constant vibrations and movement from driving, and these issues tend to get worse, causing parts to wear out faster and possibly leading to system breakdowns. Bottom line? Spotting and fixing these common problems is key to keeping your car’s electrical system running smoothly and lasting longer.

Best Practices for Selecting Quality Automotive Wire Connectors

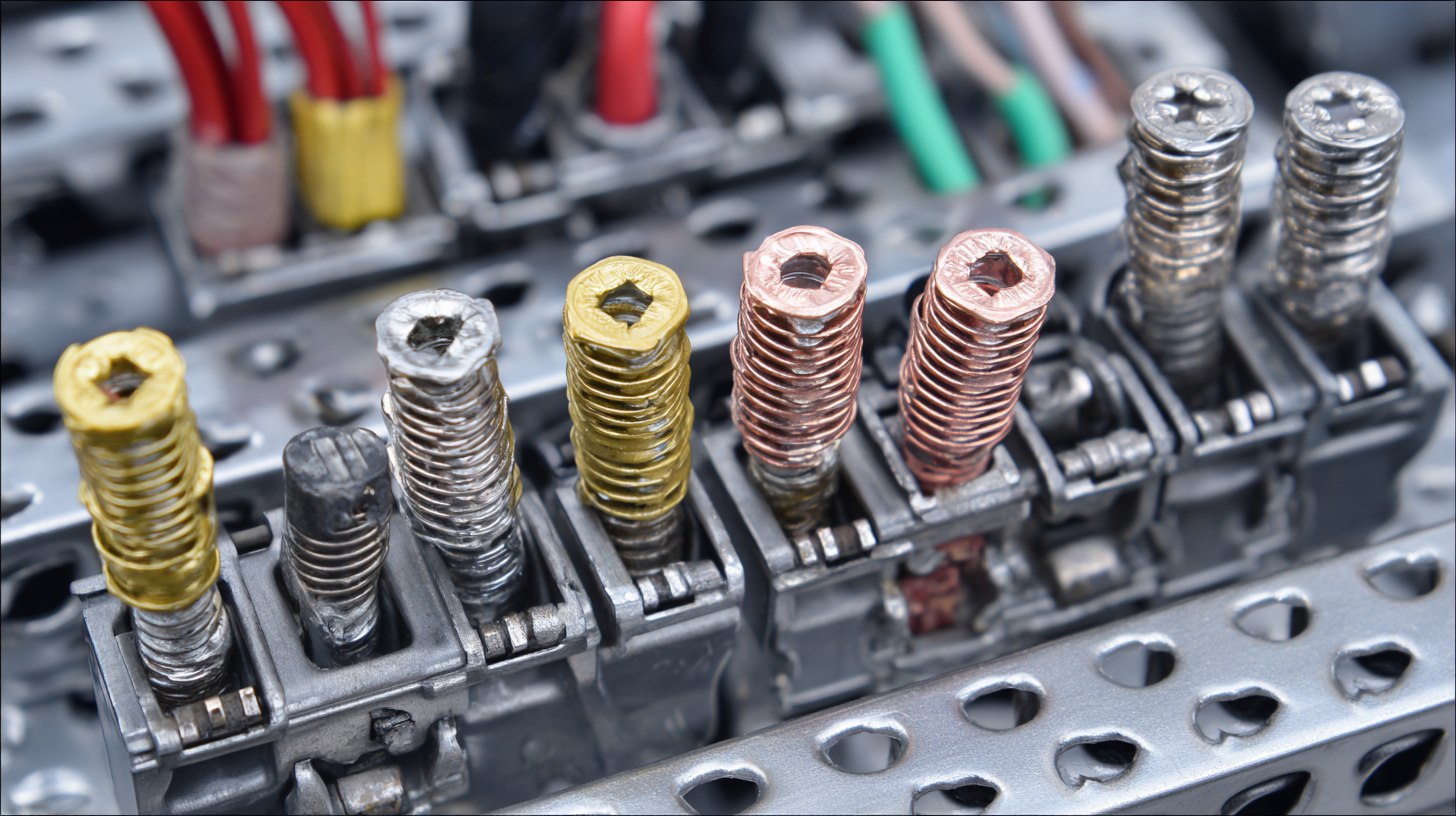

When you're choosing good quality automotive wire connectors, there are a few things you really wanna keep in mind to make sure they work well, even in tough conditions. First off, it's super important to look at what the connectors are made of. Top-notch connectors usually use materials like gold, tin, or silver-plated copper — these help them last longer and keep the connection steady, no matter the environment.

Oh, and don’t forget about insulation! Pick connectors with strong, durable insulation that can stand up to moisture, dust, and extreme temps, so you avoid shorts and damage down the line.

Oh, and don’t forget about insulation! Pick connectors with strong, durable insulation that can stand up to moisture, dust, and extreme temps, so you avoid shorts and damage down the line.

Another thing to consider is how the connector is built and whether it’s compatible with your specific vehicle setup. They come in all sorts of shapes, sizes, and keying options, so it’s kinda like finding the perfect puzzle piece that fits just right into your wiring harness. And honestly, it’s smart to go for connectors that meet industry standards and certifications — that means they’ve been tested and proven safe and reliable.

By paying attention to these little details, automotive pros can cut down on failures and keep the electrical system running smooth as butter.

Essential Tools for Efficient Installation and Maintenance of Wire Terminals

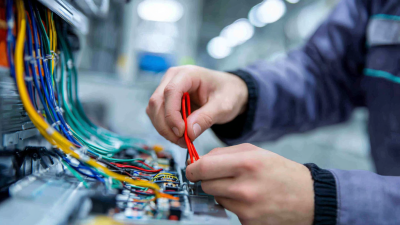

When you're working with automotive wire terminals and connectors, having the right tools can make a huge difference. A solid set of tools makes the job go smoother and helps prevent mistakes that could cause electrical issues later on. Some of the must-have tools include wire strippers, crimping pliers, and soldering gear. Wire strippers are great for prepping wires—they remove the insulation without messing up the conductor, which is super important.

Crimping tools, on the other hand, make sure the terminal and wire are really securely connected—that's key for things to work reliably.

Don’t forget about maintenance stuff like dielectric grease—this stuff really helps keep things from corroding over time. And a multimeter? Totally essential. It’s your go-to for troubleshooting because you can measure voltage, current, and resistance with it—pretty handy.

Investing in good quality tools designed for automotive work pays off in the long run, making your wiring jobs safer and way more efficient. All in all, knowing which tools you need for installation and fixes can really make your life easier and avoid a lot of headaches when dealing with automotive wire terminals and connectors.

Key Factors Influencing the Longevity of Automotive Connectors

The lifespan of automotive connectors really depends on a few key things that manufacturers and designers need to keep in mind. First off, the materials used in those connectors and terminals make a huge difference. Using high-quality stuff, like corrosion-resistant metals and tough plastics, is super important to help them stand up to tough environmental conditions — think extreme heat, moisture, or exposure to chemicals. When engineers pick the right materials, they can seriously boost how long these connectors last, making sure they perform reliably over the entire life of the vehicle.

Another big piece of the puzzle is how the connectors are designed and manufactured. Paying attention to the details during the design phase is crucial so everything fits just right and makes reliable electrical connections. On the manufacturing side, sticking to strict quality control is a must. Small mistakes, like poor sealing or rough surface finishes, can lead to early failures because of things like oxidation or wear and tear. Plus, implementing proper strain relief — that’s a fancy way of saying measures to reduce stress on the connectors — helps prevent damage when the vehicle is in use, which really extends their lifespan. When you focus on these factors, the auto industry can boost the durability and reliability of wire terminals and connectors, making vehicles safer and more dependable overall.

Troubleshooting: Diagnosing Connection Failures in Automotive Wiring Systems

Connection issues in your car’s wiring can cause more problems than you might think—things like performance hiccups or even safety concerns. Interestingly, reports show that about 30% of electrical failures in vehicles are due to crappy connections, which really highlights how important it is to have solid wire terminals and connectors. Figuring out what's wrong usually means taking a scanner of sorts—checking the wires for any damage, making sure the connectors are tight and secure, and looking out for corrosion. Start by inspecting for obvious signs of wear and tear, and double-check that there’s no dirt or moisture lurking around the connectors. Honestly, a lot of electrical gremlins tend to show up in the wiring harnesses, so they should definitely be on your radar when troubleshooting.

A couple of tips to keep in mind: giving your wiring system some regular TLC can save you a ton of cash down the road. Make it a habit to clean and tighten all those connections during your routine checks. Applying some dielectric grease on the connectors can go a long way—this little trick helps keep out moisture and corrosion, making the connectors last way longer. According to a study by the Society of Automotive Engineers, these simple preventive steps could cut electrical failures by as much as 40%.

And don’t forget, using tools like multimeters and circuit testers can really speed things up. They help you find issues like voltage drops or unwanted resistance somewhere in your wiring. The Automotive Service Association also points out that catching and fixing wiring problems early can save shop techs up to 20% on labor costs. So, basically, quick, accurate troubleshooting isn’t just good practice—it’s key to keeping your ride running smoothly and safely.

Maintenance Tips to Prevent Common Wiring Issues in Vehicles

When it comes to keeping your car running smoothly, taking good care of your wiring system is a must. Honestly, wiring problems can cause all sorts of headaches—stuff like flickering lights or, worse, your whole electrical system crashing. So, it's a good idea to stay on top of regular maintenance to keep things in check.

One simple yet important tip is to give all your wire terminals and connectors a quick inspection now and then. Look for any signs of corrosion or rust — those little issues can mess with the electrical flow and lead to performance hiccups. If you spot corrosion, just grab a gentle, non-abrasive cleaner and carefully tidy up those areas. And make sure those connections are tight and secure!

It’s also a smart move to protect your wiring from getting scraped or damaged. Wrapping vulnerable wires with protective sleeves or covers does wonders for longevity. Plus, keeping the inside of your car and the engine bay clean and free of clutter helps prevent unnecessary wear and tear on the wires. If you notice any damage or wear, don’t wait—fix it ASAP to avoid bigger, more costly repairs later on.

Understanding the Common Challenges in Automotive Wire Terminals and Connectors - Maintenance Tips to Prevent Common Wiring Issues in Vehicles

| Challenge | Description | Maintenance Tip |

|---|---|---|

| Corrosion | Electrochemical corrosion can damage terminals and connectors, leading to poor connections. | Regularly inspect connectors and apply dielectric grease to prevent moisture intrusion. |

| Loose Connections | Vibration can cause connectors to become loose over time, leading to intermittent faults. | Ensure connections are firmly engaged and use locking connectors where possible. |

| Wire Insulation Damage | Physical wear or exposure to chemicals can damage wire insulation, leading to shorts. | Inspect wire insulation and replace frayed wires promptly to avoid shorts. |

| Overloading | Exceeding the current rating for terminals can cause overheating and failure. | Ensure that terminals are rated for the electrical load and upgrade if necessary. |

| Improper Crimping | Poor crimping techniques can lead to weak connections that may fail. | Use proper crimping tools and techniques to ensure a secure connection. |

Maximizing Efficiency in Automotive Wiring: Insights on 30 Pin Auto Connectors and Terminal 2005499-8 from 2023 Industry Reports

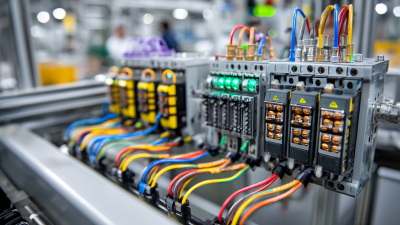

In the ever-evolving automotive industry, maximizing efficiency in wiring systems is crucial for ensuring seamless vehicle performance. One of the key components in modern automotive wiring is the 30 Pin Auto Connector, particularly the model 2005499-8. According to the 2023 industry reports, this connector is gaining traction due to its robust design and reliability in electronic applications. The 2005499-8 connector supports both male and female configurations, making it versatile for various automotive electronic systems.

Manufactured by HAIDIE in the United States, the model 2005499-8 is built to meet the stringent quality standards outlined by IATF 16949 certification. This certification ensures that the connector adheres to the highest manufacturing processes, thereby enhancing the overall durability and efficiency of automotive wiring systems. With a minimum order quantity of just one piece, integrating this connector into your automotive applications is both feasible and economical. As the industry focuses on innovation and efficiency, investing in high-quality connectors like the 21092500171 BELL CODE variant is an essential step towards optimizing automotive electronic networks.

FAQS

: High-quality automotive wire connectors are commonly made from corrosion-resistant materials such as gold, tin, or silver-plated copper to enhance longevity and maintain conductivity.

Using connectors with durable insulation is essential as it helps prevent shorts and damage caused by environmental factors such as moisture, dust, and extreme temperatures.

It's crucial to evaluate the connector's design and ensure it fits seamlessly into the vehicle's wiring harness, taking into account various shapes, sizes, and keying options.

Connectors that meet industry standards and certifications have undergone rigorous testing for safety and performance, which minimizes the risk of failures in automotive applications.

Essential tools include wire strippers for removing insulation, crimping tools for secure connections, and soldering equipment, all of which streamline the installation process.

Dielectric grease prevents corrosion, enhancing the longevity of wire terminals and ensuring reliable electrical connections over time.

A multimeter is crucial for troubleshooting as it allows technicians to accurately measure voltage, current, and resistance, leading to better diagnostics and repairs.

Key factors include the materials used, precision in design and manufacturing processes, and the implementation of strain relief mechanisms to reduce stress during operation.

High-quality, corrosion-resistant materials ensure connectors withstand harsh environmental conditions and significantly enhance their life expectancy.

Adhering to strict quality control measures during the manufacturing process, ensuring proper sealing, and avoiding surface inconsistencies are crucial for preventing premature connector failure.

Conclusion

When it comes to automotive wire terminals and connectors, there are quite a few common hiccups that can really mess with your vehicle's performance and safety. Things like bad connections, rust, or not sealing things up properly can cause some serious wiring issues down the line. To keep everything running smoothly, it’s a good idea to follow best practices—like choosing quality connectors, using the right tools for installation and maintenance, and understanding what really affects how long these parts last.

And don’t forget, staying on top of troubleshooting and doing regular check-ups can save you a lot of headaches. It’s all about catching problems early before they turn into bigger, more costly issues. At Yueqing Haidie Electric Co., Ltd., we take pride in offering top-notch wire harness solutions specifically designed for automotive needs. Our dedication to quality has earned us great feedback from customers—because we aim to deliver reliable, efficient wiring components that meet their expectations and keep their vehicles running smoothly.

Related Posts

-

The Future of Innovation in Harness Connectors for Smart Technology

-

Benefits of Choosing the Best Car Pigtail for Enhanced Vehicle Performance

-

5 Key Benefits of Auto Wire Harness in Modern Automotive Manufacturing

-

Proudly Made in China Best Elevator Connector for a Global Market

-

7 Essential Tips for Choosing the Best Car Cable Connectors for Your Vehicle

-

5 Reasons Why Board To Wire Connections Drive 30 Percent More Efficiency in Industrial Applications

Blog Tags: