Challenges Faced with Video Wire Connectors for Optimal Performance

Table of Contents

- Benefits of High-Quality Video Wire Connectors for Signal Integrity

- Impact of Connector Design on Video Transmission Quality

- Industry Standards: Ensuring Compliance for Optimal Performance

- The Role of Materials in Enhancing Connector Durability and Functionality

- Reducing Interference: Advanced Shielding Techniques for Video Connectors

- Cost vs. Performance: Evaluating the ROI of Premium Video Wire Connectors

- Essential Guide to 4 Pole Female Cable Wire Connectors for Optimizing Your Video Systems

- FAQS

- Conclusion

- Related Posts

In today's fast-changing world of electronic connectivity, Video Wire Connectors are more and more becoming a must-have for making sure everything runs smoothly across different applications—especially in the auto industry. I recently came across a report from MarketsandMarkets that says the global market for video connectors could hit around $12 billion by 2025. That’s mainly because everyone’s craving higher-quality video and stronger, more reliable connectivity.

Our company, Yueqing Haidie Electric Co., Ltd., is right there at the forefront of this trend. We focus on crafting wire harness solutions that are tailored specifically for auto parts manufacturers. We’re all about high quality and innovative design, which has really helped us earn a solid reputation. It’s exciting because it means we can truly help tackle the challenges Video Wire Connectors face—like ensuring reliability and top performance. As we dig deeper into these challenges, it’s clear just how much they can impact overall system efficiency and, ultimately, how happy end-users are with the products they've got.

Our company, Yueqing Haidie Electric Co., Ltd., is right there at the forefront of this trend. We focus on crafting wire harness solutions that are tailored specifically for auto parts manufacturers. We’re all about high quality and innovative design, which has really helped us earn a solid reputation. It’s exciting because it means we can truly help tackle the challenges Video Wire Connectors face—like ensuring reliability and top performance. As we dig deeper into these challenges, it’s clear just how much they can impact overall system efficiency and, ultimately, how happy end-users are with the products they've got.

Benefits of High-Quality Video Wire Connectors for Signal Integrity

High-quality video wire connectors are kind of a big deal when it comes to keeping your signal clear, especially if you're dealing with high-definition or professional video setups. I read somewhere from the Electronics Industry Association (EIA) that almost 70% of video problems boil down to using cheap or poor-quality connectors and cables—that really shows you why it pays to invest in better gear. These top-notch connectors often use special materials and shielding tech to make sure your video signals don’t get degraded or interfered with.

High-quality video wire connectors are kind of a big deal when it comes to keeping your signal clear, especially if you're dealing with high-definition or professional video setups. I read somewhere from the Electronics Industry Association (EIA) that almost 70% of video problems boil down to using cheap or poor-quality connectors and cables—that really shows you why it pays to invest in better gear. These top-notch connectors often use special materials and shielding tech to make sure your video signals don’t get degraded or interfered with.

Plus, a study by the National Institute of Standards and Technology (NIST) found that systems with premium connectors showed about 40% less signal noise compared to those with standard ones. That difference can be a game-changer, especially in professional environments like broadcasting or filmmaking where every detail counts. And with 4K and 8K video becoming the norm, how good your connectors are can seriously impact your whole setup. Basically, high-quality video wire connectors aren’t just about making things work—they help you get the most out of your gear and keep your investments secure for the long haul.

Impact of Connector Design on Video Transmission Quality

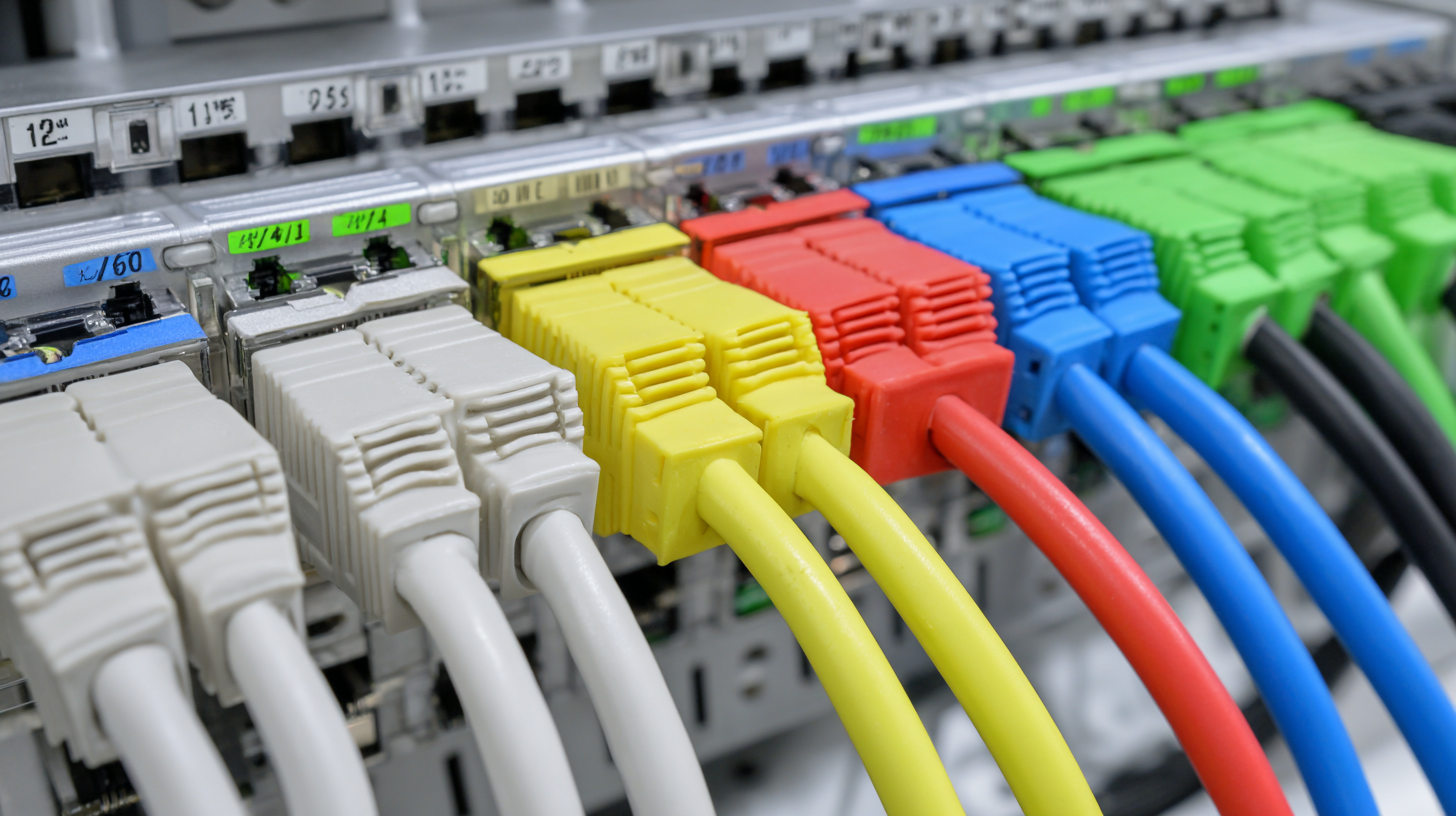

When it comes to video wire connectors, their design really matters for how good your video quality ends up being. If you’re using a connector that isn’t well-made, you might notice your picture gets blurry or the signal keeps dropping—that’s no fun. Things like what the connector is made of, its shape, and how well the contacts connect all play a part in how smoothly everything runs. For instance, connectors crafted from high-quality metals that conduct electricity well will usually give you less signal loss. And if the connector threads in securely, it helps keep that video feed stable and free from interference.

A few simple tips to keep things working perfectly? First, make sure your connectors are nice and snug, and they’re free from dust or dirt—that stuff can mess things up. It’s also a good idea to check periodically for signs of wear or damage so you’re not caught off guard during an important moment. When choosing connectors, pick ones made specifically for your type of video signal—whether it’s HDMI, DisplayPort, or something else—to get the best compatibility and performance.

Oh, and don’t forget about cable length! Longer cables tend to weaken the signal, so it’s better to opt for shorter, high-quality cables whenever you can. And finally, go for connectors with solid shielding—they help fend off electromagnetic interference, which can otherwise cause the picture to get grainy or flicker. Keep these tips in mind, and you’ll enjoy a clearer, more reliable video experience.

Industry Standards: Ensuring Compliance for Optimal Performance

When it comes to video wire connectors, sticking to industry standards is super important if you want things to work smoothly. The tech world keeps evolving so fast, and that means connectors need to do more than just work—they’ve gotta meet strict rules and regulations too. When manufacturers follow these standards, it’s like ensuring their connectors can handle high-speed data without losing quality or messing up with interference. Of course, staying on top of these evolving standards isn’t always easy; it requires constantly tweaking designs and materials, which can be quite a challenge sometimes.

And let’s not forget, compatibility with different video formats adds another layer of complexity. With newer tech like 4K and 8K screens coming out, connectors need to support faster data transfer and also be easier to handle and install. Meeting these standards means going through lots of testing and validation to make sure everything works well across various uses. By focusing on industry benchmarks, manufacturers can boost the quality and reliability of their products, making users feel more confident. All in all, it’s about creating video connectors that are reliable, future-proof, and easy to use—whether you’re a casual viewer or a pro in the field.

The Role of Materials in Enhancing Connector Durability and Functionality

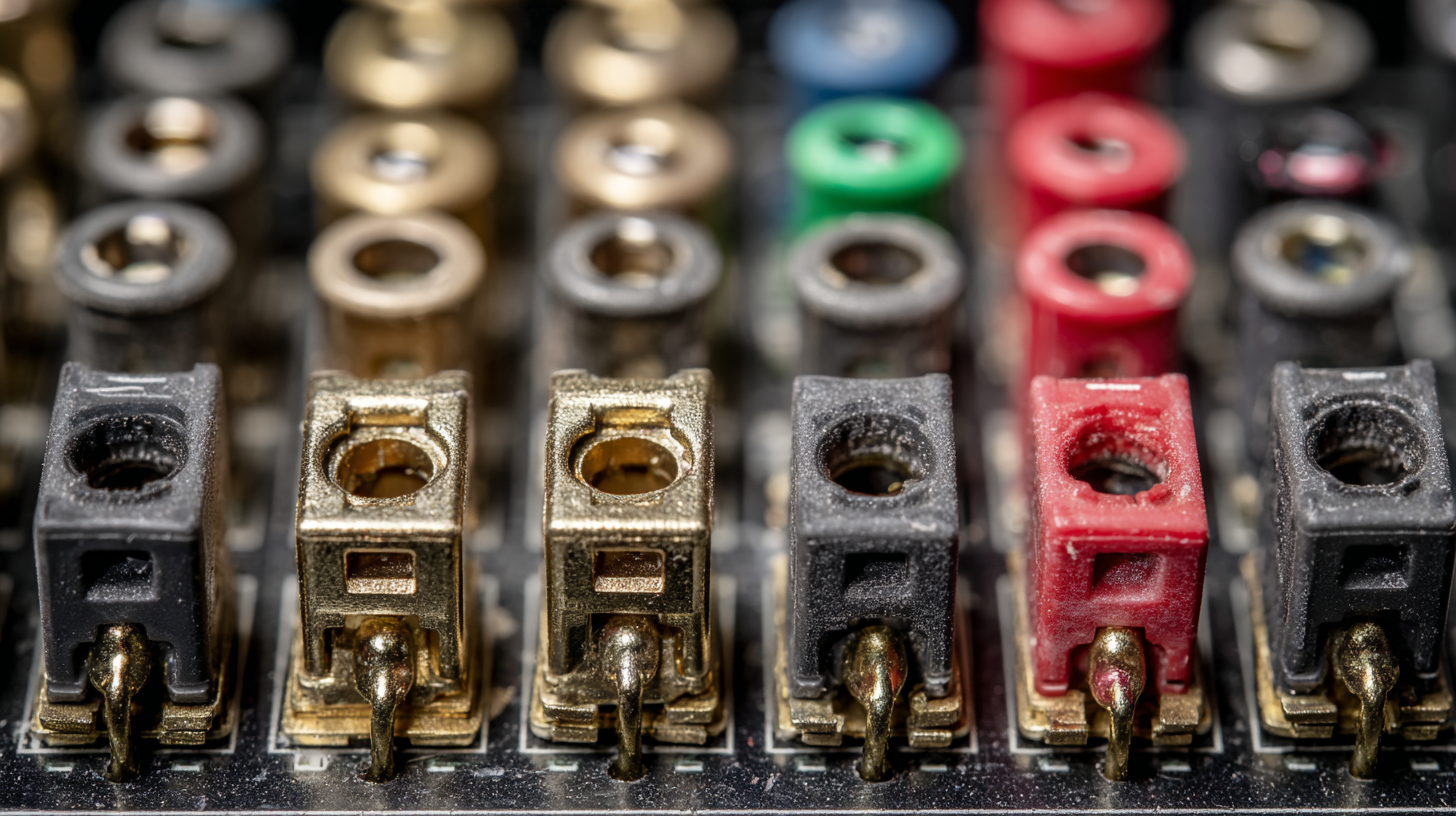

When you think about video wire connectors, the materials they're made from really matter—they influence how long they last and how well they work. Using top-notch materials not only makes the connectors sturdier physically but also helps them perform better in different environments. For example, connectors with gold-plated contacts tend to conduct signals more smoothly and resist corrosion, meaning you can count on them to stay reliable over time. On the flip side, materials like polycarbonate or thermoplastic elastomers give a bit of flexibility and impact resistance—pretty important if the connectors are used a lot or in rough conditions.

And here's pretty interesting: with the rise of new composite materials, designers are finding smarter ways to build connectors. These new materials can be lightweight but still strong, so the connectors aren’t bulky but still durable. That's huge, especially when space is tight or when the connectors are frequently moved around—that lighter weight makes installation easier and helps fight off wear and tear. As more people demand high-performance video connections, choosing the right materials remains a key factor in making sure connectors last and work well over time.

Challenges Faced with Video Wire Connectors for Optimal Performance - The Role of Materials in Enhancing Connector Durability and Functionality

| Material Type | Durability Rating (out of 10) | Corrosion Resistance | Cost Effectiveness ($/unit) | Common Applications |

|---|---|---|---|---|

| Copper | 9 | High | $0.50 | Audio/Video connections |

| Aluminum | 7 | Moderate | $0.30 | General wiring solutions |

| Gold Plated | 10 | Very High | $1.00 | High-end audio/video systems |

| Plastic | 5 | Low | $0.10 | Low-cost applications |

| Titanium | 8 | High | $2.00 | Industrial applications |

Reducing Interference: Advanced Shielding Techniques for Video Connectors

When it comes to streaming and video setups, cutting down on interference really makes all the difference for getting that smooth, high-quality picture. Advanced shielding techniques are pretty much essential these days—they help block out electromagnetic and radio-frequency interference (EMI/RFI) that can mess with the video and audio quality. As technology keeps getting better, having HDMI cables and connectors with clever, innovative shielding isn’t just a nice upgrade — it's actually becoming a must-have. These better shielding methods do more than just protect your signals; they also improve your overall experience, especially in situations where you really need things to run smoothly and reliably.

Even in aerospace and defense, where protecting sensitive systems is critical, they use top-tier materials and smart design strategies for EMI/RFI shielding. And guess what? That same level of protection is now making its way into consumer electronics. For example, premium HDMI cables meant for gaming or watching high-def content now come with advanced shielding to keep noise and artifacts at bay, so your picture stays sharp and clear without distractions. Looking ahead to 2025, understanding these new shielding techs will be super helpful—whether you’re gaming, streaming, or working professionally, making sure your setup is well-shielded will definitely give you an edge.

Challenges Faced with Video Wire Connectors for Optimal Performance

This chart illustrates the various factors affecting the performance of video wire connectors and their impact on interference levels. Effective shielding, connector quality, proper installation techniques, environmental influences, and cable length are critical to optimizing video signal quality.

Cost vs. Performance: Evaluating the ROI of Premium Video Wire Connectors

When it comes to video wire connectors, it’s pretty common to get into debates about cost versus performance. High-quality connectors are built to give you

better signal quality, less interference, and longer-lasting durability—things that really matter for high-definition video setups. But here’s the thing: those premium connectors usually come with a bigger price tag, so it’s natural to wonder whether the extra bucks are worth it, whether it’s for work or just your home setup.

Figuring out if it’s worth the investment really depends on how you plan to use them. For pros who rely on

crystal-clear video quality for their projects, spending more upfront on better connectors often pays off in the long run. After all, a single event or shoot can hinge on whether your gear holds up, and skimping might end up costing you more in damage or lost opportunities. On the flip side, if you’re just a casual user who isn’t super picky about tiny quality differences, regular connectors might do just fine. They save you some money and still give you decent viewing. In the end, it’s all about finding that sweet spot between what you need, what you value, and what fits in your budget.

Essential Guide to 4 Pole Female Cable Wire Connectors for Optimizing Your Video Systems

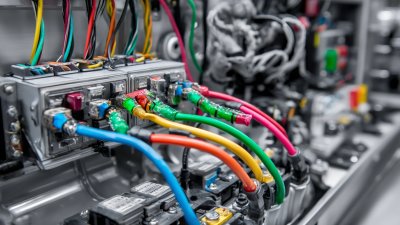

When it comes to enhancing video systems, the choice of cable wire connectors can significantly impact performance and reliability. The 4 Pole Female Cable Wire Connector, specifically the product known as 6189-1231, stands out as an essential component in optimizing your video connections. This connector is designed to ensure a secure, high-quality connection that minimizes signal loss and interference, which is crucial for achieving the best video output.

The design of the 6189-1231 connector allows for easy installation and maintenance, making it a great choice for both professionals and DIY enthusiasts alike. With its robust construction, it is engineered to withstand the rigors of frequent use while maintaining optimal performance. The four poles provide a reliable pathway for video signals, ensuring that your system can operate smoothly during critical moments. Whether you are setting up a new video system or upgrading an existing one, incorporating this connector will enhance your overall setup.

In addition to its performance benefits, the 6189-1231 connector is also versatile, making it suitable for a variety of applications, from home theaters to professional video production environments. Its compatibility with different wiring systems ensures that you can achieve the best possible integration without the need for multiple connector types. Adopting such a quality component not only simplifies your connections but also elevates your video system to new heights of reliability and clarity.

FAQS

: High-quality video wire connectors help maintain signal integrity, reduce signal loss and interference, and improve overall performance in high-definition and professional video applications.

Nearly 70% of video transmission issues are linked to poor-quality connectors and cabling, leading to degraded signals and interruptions in video feeds.

A study by the National Institute of Standards and Technology found that premium connectors can reduce signal noise by 40% compared to standard connectors, improving clarity and precision.

The design of video wire connectors affects signal degradation; factors like material choice, geometry, and contact integrity are crucial for ensuring reliable and clear video feeds.

It’s essential to ensure connectors are tightly fitted and free from dust, inspect them regularly for wear, and use connectors specific to the video signal type.

Longer cables can lead to signal attenuation, so keeping cable lengths as short as necessary can minimize potential signal loss and enhance video quality.

Look for connectors made from high-quality metals with good conductivity, secure connection designs, and effective shielding against electromagnetic interference to ensure stable video transmission.

Investing in high-quality video wire connectors secures long-term performance and reliability in audio-visual setups, especially with increasing demands for higher video resolutions like 4K and 8K.

Yes, connectors made from high-quality materials that ensure excellent conductivity can help minimize signal loss and enhance the overall clarity of video transmissions.

Conclusion

In the blog titled "Challenges Faced with Video Wire Connectors for Optimal Performance," we really dive into why having high-quality video wire connectors is so important for keeping your signal clear and strong during video transmissions. It’s quite fascinating how much the design of a connector can actually affect the overall video quality—something that many might overlook. The article also stresses how following industry standards isn’t just a rule to follow, but actually crucial if you want things to run smoothly at peak performance. Plus, it talks about how the materials used in these connectors can make a difference not just in durability but in how well they function. And let’s not forget about shielding techniques—those are key to cutting down on interference and getting a cleaner, crisper signal.

On top of that, the blog gives some good insights into the whole cost versus performance debate. It’s really handy if you’re trying to figure out whether spending a bit more on premium connectors is worth it in the long run. Since Yueqing Haidie Electric Co., Ltd. specializes in high-quality wire harness solutions, we understand what it takes to meet industry needs for reliable connectors—so that our clients can count on top-notch performance in their video systems. Basically, it’s all about helping everyone get the best possible setup without breaking the bank.

Related Posts

-

Navigating the Future Market of Hirschmann Connectors by 2025 with Expert Insights and Practical Steps

-

Ultimate Guide to Choosing the Best Vehicle Wiring Connectors for Your Needs

-

China's Best Motorcycle Connector: A Trusted Quality for Global Buyers

-

7 Essential Tips for Choosing the Best Auto Wiring Harness: Optimize Your Production with 30% Less Downtime

-

How to Choose the Right VW Connector for Your Automotive Needs

-

2025 Automotive Connector Trends: An In-Depth Comparison of the Best Connectors in Car Technology

Blog Tags: