7 Essential Electrical Wire Types Every Electrician Should Know

Table of Contents

- Understanding the Basics of Electrical Wire Types

- Common Uses for THHN and THWN Electrical Wires

- Exploring the Versatility of Romex Cable in Residential Wiring

- The Importance of UF Wire for Outdoor Electrical Installations

- Factors to Consider When Choosing Low-Voltage Wire Types

- A Guide to Specialty Wires: NM-B, SE, and MC Cable Applications

- Optimizing Automotive Wiring: The Role of the 80PIN 1318751-7 PCB Header in Electrical Connectivity

- FAQS

- Conclusion

- Related Posts

In the fast-changing world of electrical work, it’s really important for every electrician to understand the different types of electrical wires out there. At Yueqing Haidie Electric Co., Ltd., we get it—knowing your wire types isn’t just about technical know-how; it’s key to keeping electrical systems safe and working smoothly, especially when it comes to auto parts. We pride ourselves on delivering top-notch wire harness solutions, and because of that, we’ve earned a solid reputation among our customers. This blog’s gonna break down the seven main types of electrical wires that every electrician should be familiar with. Having this knowledge not only helps you make smarter choices for your projects, but it also boosts the quality of your work and keeps your clients happy with reliable electrical systems. Whether it’s durability, conductivity, or just knowing what wire to use, getting the hang of these types makes all the difference in the long run.

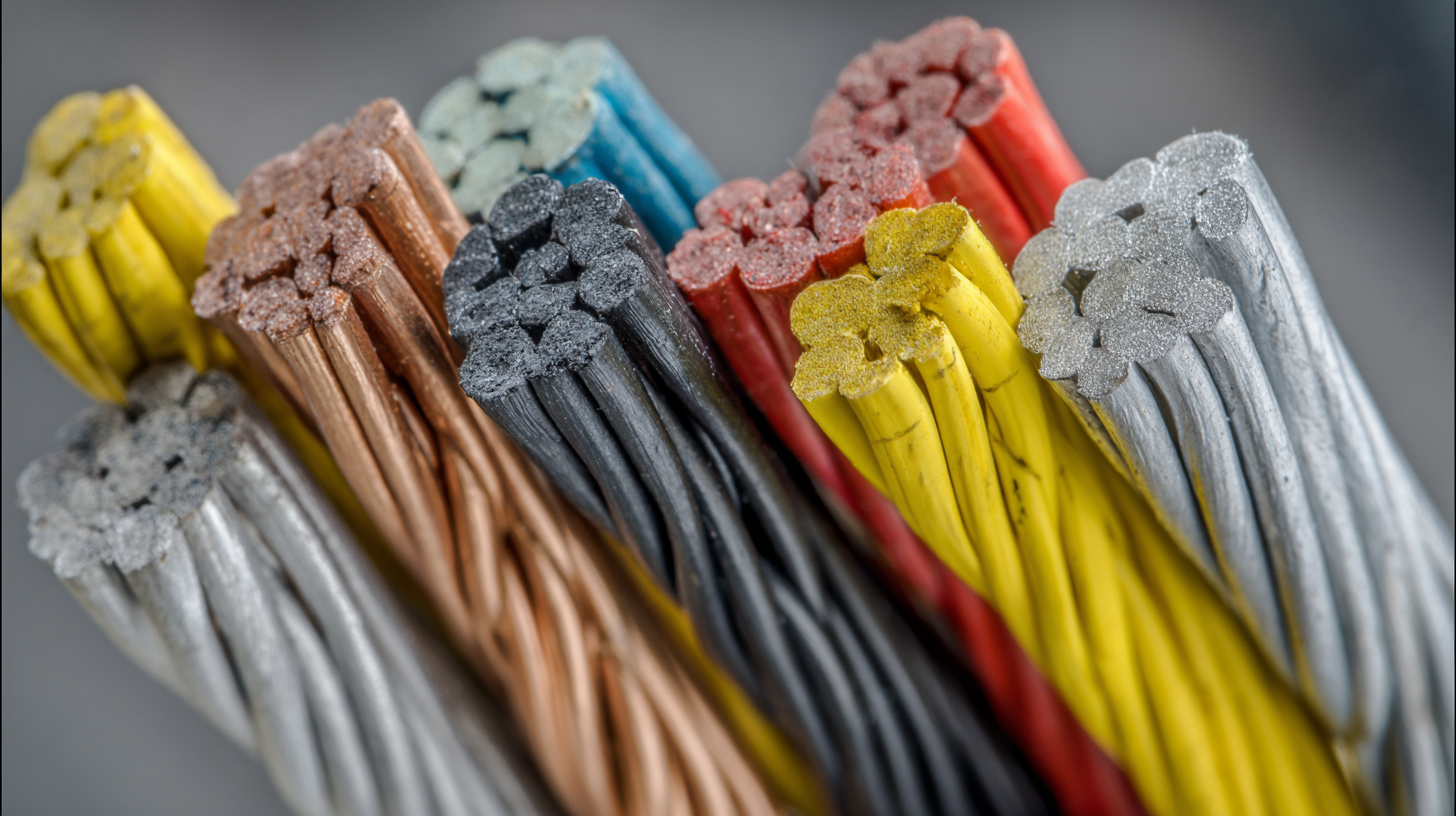

Understanding the Basics of Electrical Wire Types

Getting a solid grasp of the different types of electrical wires is pretty important if you're an electrician. Each kind of wire has its own specific purpose, whether you're working on a home, a business, or even bigger industrial setups. For example, there’s the good old non-metallic (NM) cables — most folks call them Romex. These are super common for indoor wiring in houses because they're lightweight and flexible, making installation a lot easier. They come with insulated conductors wrapped in a plastic sheath, which adds both safety and convenience.

Then there’s the armored cable, or AC, which is basically a wire with a protective metal layer around it. That extra armor makes it way tougher and helps prevent damage, which is a big deal in places where the wires might be subjected to physical stress or other hazards. Don’t forget about specialty wires too, like THHN — that’s thermoplastic, high heat-resistant nylon-coated wiring. You’ll mostly see these in commercial or industrial settings where high temps are a concern. Knowing the ins and outs of these basic wire types not only helps you pick the right wire for each job but also makes sure you’re following safety rules and electrical codes like a pro.

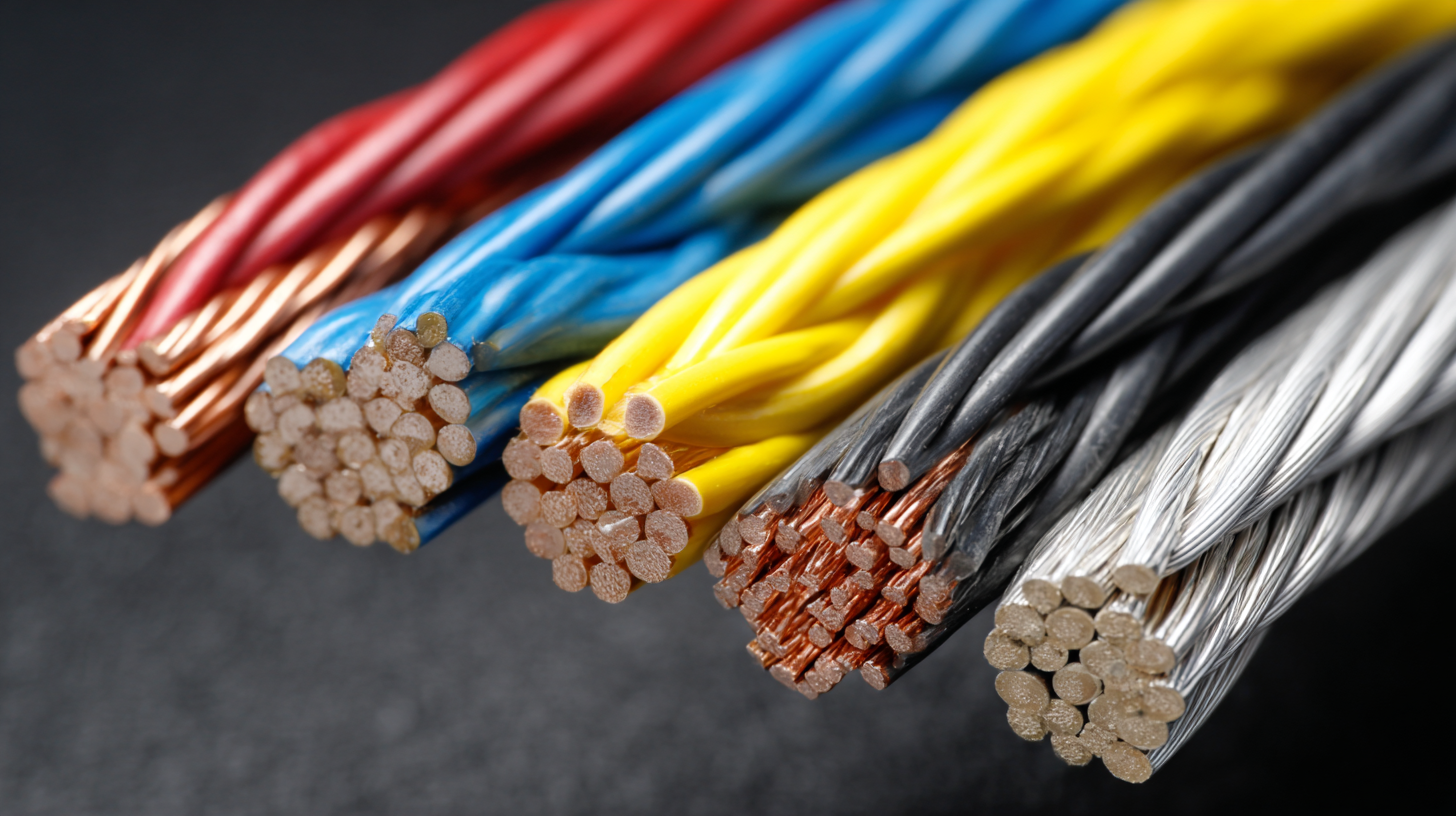

Common Uses for THHN and THWN Electrical Wires

When you're dealing with electrical wiring, it’s pretty important to get a handle on what different wire types are actually good for. I mean, there’s a whole bunch of options out there, but two of the most common ones you’ll run into are THHN and THWN wires. According to the National Electrical Code, THHN wires can handle high temperatures, which is why they’re typically used in conduit runs and in pretty heavy-duty commercial setups. They can handle heat up to about 90°C, making them a solid choice for industrial environments where things tend to get pretty hot.

On the flip side, THWN wires are super versatile—they work well in both damp and dry places since they’re built to resist moisture and some chemicals. That makes them perfect for outdoor jobs or even underground work where things get wet or muddy. Some research from the Electrical Safety Foundation International (ESFI) shows that choosing the right wire type isn’t just about convenience—it really helps prevent stuff like short circuits and fires. So yeah, picking the right wire isn’t just a technical detail; it’s a big deal for keeping everything safe and running smoothly. That’s why THHN and THWN wires are so important—they do the heavy lifting, literally, for electrical safety and reliability.”

Exploring the Versatility of Romex Cable in Residential Wiring

You know, Romex cable—officially called NM or non-metallic cable—has pretty much become the go-to in residential wiring these days. It’s loved for being versatile and super easy to work with. Basically, it’s made up of a bunch of insulated wires wrapped inside a tough plastic sheath, which makes installing it a lot simpler while still keeping everything safe and secure. According to the folks at the National Electrical Contractors Association, more than 70% of electricians prefer using Romex for inside wiring jobs. That really shows how dominant it is in the home wiring scene.

When it comes to how well it performs, Romex can handle a bunch of different situations. For example, NM-B types are great because they work both indoors and outdoors—if you install them right, of course. The plastic coating provides good moisture resistance, which helps prevent electrical shorts. Interestingly, a report from the National Fire Protection Association mentions that using proper wiring, especially with materials like Romex, has helped reduce electrical fires in homes by about 20% over the past decade. No kidding, it’s not just about making wiring easier—it’s actually making our homes safer too.

The Importance of UF Wire for Outdoor Electrical Installations

When you're working on outdoor electrical wiring, choosing the right kind of wire isn't just a good idea—it's pretty much essential for safety, reliable performance, and peace of mind. UF (Underground Feeder) wire really stands out in this regard. It's designed specifically for tough conditions, whether you’re burying it directly in the ground or using it in damp outdoor spots. What makes it special? Well, it’s got a moisture-resistant thermoplastic jacket that can handle all sorts of bad weather without breaking a sweat. The National Electrical Code (NEC) confirms that UF wire isn't just safe but also meets all the standards for outdoor use. That’s why many electricians tend to go for it—it's like the reliable friend you can always count on in outdoor projects.

Plus, with the growing push toward energy saving and renewable energy projects, having durable, dependable wiring like UF has become even more important, according to the Department of Energy. Electricians often face the challenge of making sure outdoor setups can cope with temperature swings and moisture—things that can really mess with wiring otherwise. In fact, a recent survey found that nearly 60% of electricians prefer UF wire because it performs so well outdoors. It helps protect your power systems from weather-related damage and keeps everything running smoothly without worries about cross-contamination or deterioration. So, getting a good grip on why UF wire matters can really boost the quality of your outdoor electrical work—giving both homeowners and electricians a bit more peace of mind.

Factors to Consider When Choosing Low-Voltage Wire Types

When you're choosing low-voltage wires, there are a few key things you definitely want to keep in mind. First off, think about what you’re actually using the wires for — different devices and environments call for different wire specs. For example, if you’re working on something automotive-related, the wires need to handle heat, chemicals, and even constant vibrations. Here at Yueqing Haidie Electric Co., Ltd., we totally get these challenges. That’s why we focus on providing top-notch wire harness solutions specifically designed for the auto parts industry, so you get durability and dependability you can count on.

Another thing to consider is the wire gauge. Thicker wires can carry more current, but they might not fit into tight spaces or flexible setups. So, always double-check the manufacturer’s specs to make sure everything’s compatible. And don’t forget about the insulation—the material around the wire matters a lot because it protects against moisture, wear and tear, and electrical noise.

**Pro tip:** Always go for wires that have the right certifications—that’s your best bet for safety and meeting standards. If you’re unsure about something, it’s never a bad idea to ask an expert to help you pick the right type. And lastly, think about where you’re going to use the wire—because the environment can really impact how long it lasts and how well it performs.

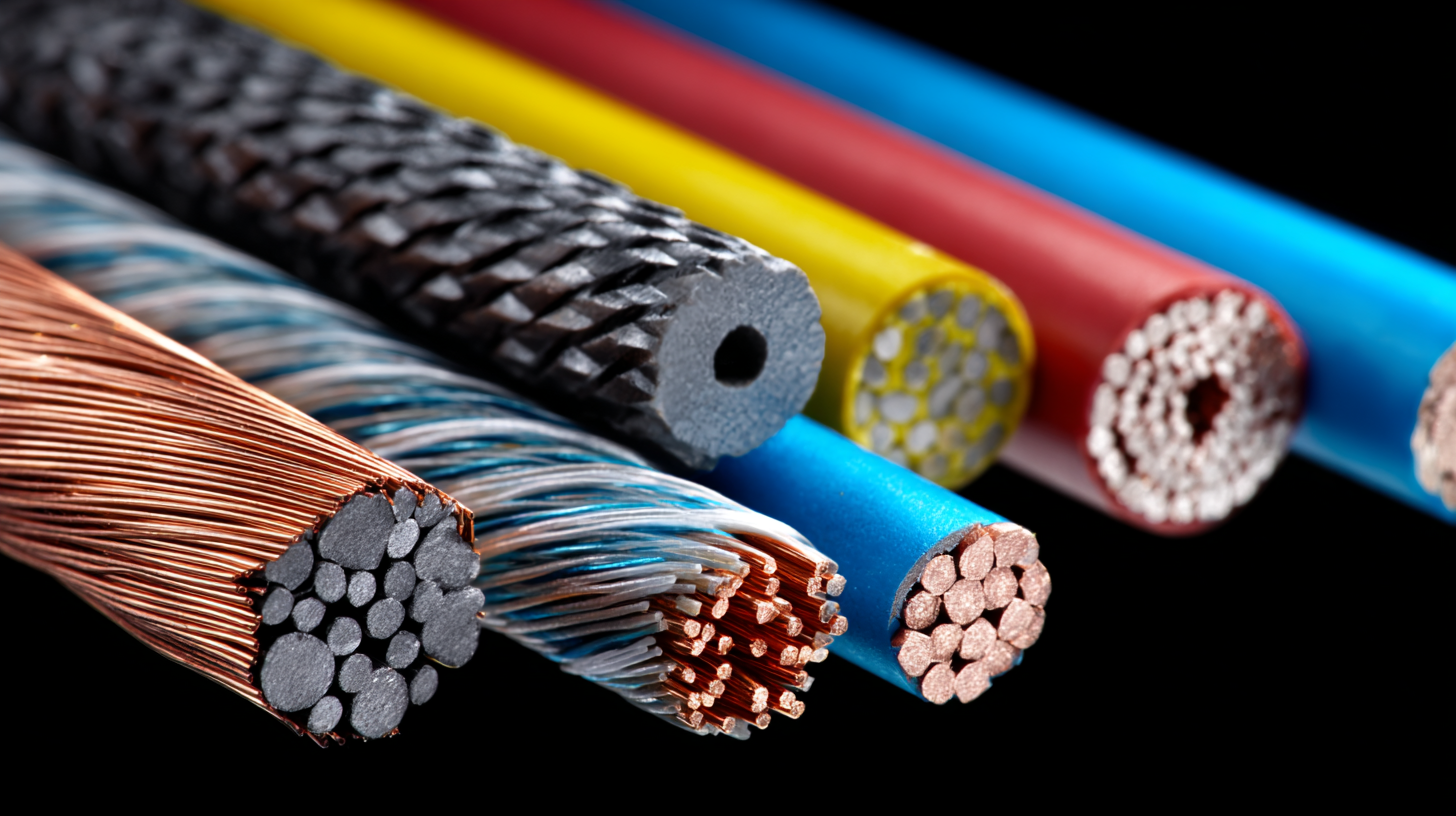

A Guide to Specialty Wires: NM-B, SE, and MC Cable Applications

When it comes to electrical installations, really understanding the different types of wires is super important for electricians. It’s not just about wiring stuff up; it’s about doing it safely and efficiently. You’ll hear a lot about wires like NM-B (that’s the non-metallic sheathed cable), SE (service entrance cables), and MC (metal-clad cable). Each one has its own special job. For example, NM-B is pretty much the go-to choice for indoor residential wiring because it’s so versatile and easy to work with. It’s copper, insulated with a PVC sheath, which makes it great for dry, indoor spots. Just a heads-up, though—keeping it away from moisture is key to avoiding any hazards.

Then there’s SE cable, which is mainly used to bring power from the utility lines into buildings. It’s built tough — rated for high voltages and designed to handle the outdoors and different weather conditions. So, it’s the way to go when you’re installing outside. And finally, MC cable comes into play mostly in commercial or industrial settings. It’s super durable because of its metal cladding, which helps protect the wires from physical damage. That makes it perfect for places where wires might take a beating.

Getting to know these specific wires and what they’re used for really helps electricians make smart choices on the job. It’s all about making sure everything is safe, reliable, and up to code.

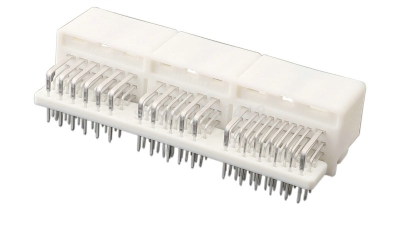

Optimizing Automotive Wiring: The Role of the 80PIN 1318751-7 PCB Header in Electrical Connectivity

In the realm of modern automotive design, optimizing electrical connectivity is paramount to ensuring robustness and reliability. The 80PIN 1318751-7 PCB header serves a crucial role in this domain, acting as a pivotal component that enhances the efficiency of wiring systems. This connector is specially designed for high-density applications, enabling seamless integration of multiple connections without compromising space or performance. Its unique crimp-type stamping method ensures a secure and lasting connection, which is essential for the demanding conditions that automotive environments often present.

The 80 pin Auto Connecting Crimp Type Stamping Female Wire Crimp Terminal 1318751-7 is tailored to meet the specific needs of automotive manufacturers. By using this terminal, engineers can improve electrical performance while minimizing potential failures due to loose or unreliable connections. The design facilitates easy installation and maintenance, allowing for quick assembly and disassembly, which can significantly streamline production processes. In addition, its robust construction ensures that it can withstand vibrations and temperature variations, further enhancing the durability of the wiring system.

Moreover, the versatility of the 80PIN connector allows it to be utilized across various automotive applications, from engine management systems to infotainment controls. As vehicles become increasingly sophisticated, the demand for reliable and efficient electrical connectivity solutions grows. The 1318751-7 consequently stands out as a preferred choice for engineers seeking to optimize wiring in their automotive designs, striking the perfect balance between performance, reliability, and ease of use.

FAQS

: Non-metallic (NM) cables, also known as Romex, are widely used for indoor wiring in homes due to their lightweight and flexibility. They consist of insulated conductors and a plastic sheath, ensuring safety and ease of installation.

Armored cable (AC) features a protective metal sheathing that provides durability and reduces the risk of damage, making it particularly useful in areas where wires may be exposed to physical stress or potential hazards.

THHN (Thermoplastic High Heat-resistant Nylon-coated) wire is designed for high-temperature applications and is commonly found in commercial and industrial settings.

Factors to consider include the intended application, wire gauge, insulation material, and compatibility with the device or environment.

Wire gauge is crucial because thicker wires can transmit more current but may not fit all designs, especially in compact spaces where flexibility is necessary.

Insulation material protects against moisture, abrasion, and electrical interference, which is vital for ensuring the wire's longevity and performance.

Choosing wires with proper certifications ensures safety and compliance with relevant electrical codes, helping to prevent potential hazards.

Consulting with a professional is advisable when in doubt about the best wire type for a project to ensure safety and compatibility.

The environment where the wire will be used significantly affects its longevity and performance, making it essential to consider environmental factors during selection.

Conclusion

Hey there! So, in our blog titled "7 Essential Electrical Wire Types Every Electrician Should Know," we dive into the different kinds of wires you'll want to be familiar with. It’s pretty much a must-read if you're into electrical work. We cover the basics, like how THHN and THWN wires are often used in industrial setups—those are pretty common, you know? Then there's Romex, which is super versatile for residential wiring projects, and UF wire, which you’ll need when you're working outside or in damp areas. Oh, and we don’t forget about low-voltage wires—what to look out for when choosing them—and we run through some of the specialty cables, like NM-B, SE, and MC cables. So, whether you’re just starting out or a seasoned pro, there’s something useful in there.

At Yueqing Haidie Electric Co., Ltd., we get how important it is to have high-quality wiring options. We’ve been providing top-notch wire harnesses for a while now, and that experience helps us understand exactly what electricians need for their projects. We’re really dedicated to delivering products that meet the highest standards, and it’s paid off — our clients trust us and keep coming back. We’re always working to improve and offer the best stuff out there, tailored to what you need most.

Related Posts

-

Top Strategies for Optimizing Your Best Motorcycle Wire Harness for Maximum Performance

-

Ultimate Guide to Choosing the Best Vehicle Wiring Connectors for Your Needs

-

7 Best Circuit Board Wire Terminals for Optimal Performance in 2023

-

How to Choose the Best Wire Auto Solutions for Your Global Sourcing Needs

-

7 Proven Benefits of Choosing the Best Connector Housing for Your Needs

-

Proudly Made in China Best Elevator Connector for a Global Market

Blog Tags: