7 Essential Tips for Choosing the Best Auto Wire Connectors Terminals

Table of Contents

- Understanding Auto Wire Connectors: Types and Applications

- Evaluating the Material Quality of Wire Connectors for Enhanced Durability

- Critical Factors: Voltage Rating and Current Carrying Capacity Explained

- Importance of Wire Gauge Compatibility in Connector Selection

- Easy Identification: How to Read Connector Specifications and Ratings

- Trends and Innovations in Auto Wire Connectors: What to Look For in 2023

- FAQS

- Conclusion

- Related Posts

You know, in today’s auto world, picking the right auto wire connectors and terminals is more important than ever. I mean, just recently, a report from MarketsandMarkets pointed out that the global wiring harness market is expected to hit around USD 74.68 billion by 2025! That really shows how crucial these little components are for both how well cars perform and how safe they are. Here at Yueqing Haidie Electric Co., Ltd., we’re right in the thick of all this. We specialize in creating custom wire harness solutions that fit the unique needs of our clients—big or small. People really trust us because we focus on quality, and we’re known for delivering reliable, top-notch wire harnesses. As automotive systems get more advanced, the role of good wire connectors becomes even more critical—not just for manufacturers but for anyone who cares about vehicle safety and performance. So basically, understanding what makes a great auto wire connector terminal is kind of a big deal these days, don’t you think?

Understanding Auto Wire Connectors: Types and Applications

When you're picking auto wire connectors, it's pretty important to understand the different types out there and what they’re used for.

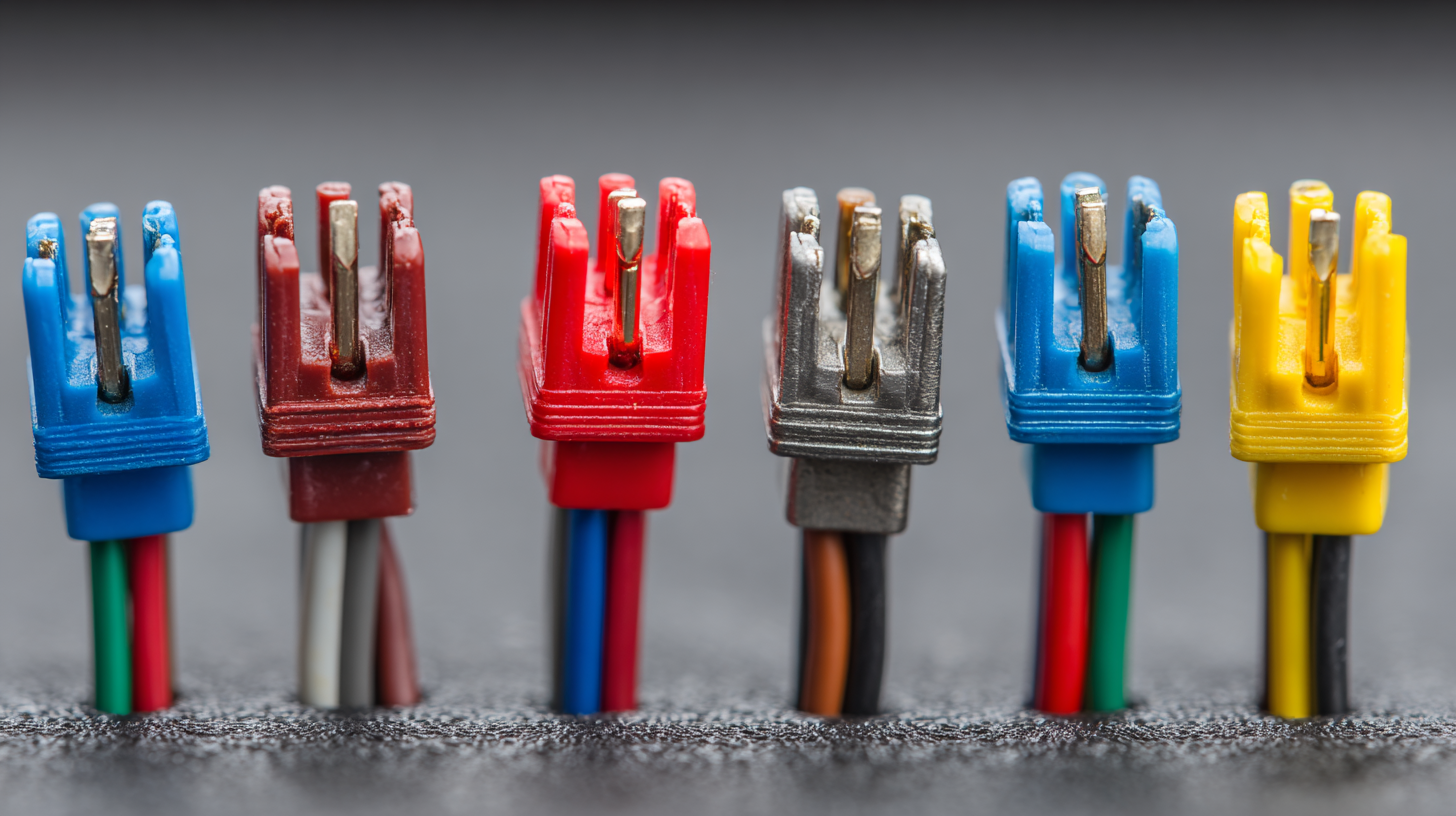

There are a few common kinds, like butt connectors, solder connectors, and spade connectors.

For example, butt connectors are great if you need to join two wires end-to-end—they give you a solid, reliable connection.

Solder connectors, on the other hand, are more of a permanent fix,

making sure there's minimal resistance and maximum conductivity, which is awesome when you're dealing with high-performance setups.

Each type of connector has its own specific purpose, and their uses can vary quite a bit.

Take spade connectors, for instance—they’re usually used for quick disconnects in automotive wiring,

so you can easily do maintenance or upgrades without a hassle.

Crimp connectors are also pretty handy for all sorts of automotive and electrical projects because they’re simple to use and pretty dependable.

Getting to know these different types and what they’re best suited for

can really help you make smarter choices, ultimately boosting your vehicle’s electrical system in terms of safety and performance.

Evaluating the Material Quality of Wire Connectors for Enhanced Durability

When you're trying to pick out the best auto wire connectors, one thing that really matters is the

quality of the materials used. I mean, according to

a report from the International Electrotechnical Commission (IEC), connectors made from top-notch

materials can last up to 50% longer than those made

with cheaper ones. That’s pretty huge, right? It just goes to show how important it is to go for

connectors crafted from good stuff—like copper for conductors and

high-grade plastics like thermoplastics for insulators—since they

can stand up to extreme temps and won’t corrode easily.

On top of that, a study by the Society of Automotive Engineers (SAE) found that connectors with

tin-plated copper are about 30% better at resisting

oxidation compared to regular copper ones. That means a more reliable connection, fewer maintenance

headaches, and less chances of system failures. Also, don’t forget about the outer coating—materials

like nylon or PVC can really

help shield the connectors from environmental damage and stretch out their lifespan, especially in

automotive settings. At the end of the day, choosing the right materials isn’t just about personal

preference; it’s a key factor that seriously impacts how well the connectors perform over time and,

ultimately, your safety too.

Critical Factors: Voltage Rating and Current Carrying Capacity Explained

When you're choosing auto wire connectors, it's really important to get a good handle on their

voltage rating and how much

current they can handle. Basically, the

voltage rating tells you the maximum voltage the connector can safely support—think of it as

its upper limit. The IEEE points out that if you pick a connector with too low of a voltage

rating, it might risk dielectric breakdown, which can cause arcing or even start a fire. In

automotive setups, you're usually working with something between 12V

and 48V, but it’s smart to go for connectors that

are rated above your system’s max voltage just to keep everything safe and running smoothly.

Now, about the current capacity—that’s simply how much current a connector can carry without

getting too hot. The ANSI recommends making sure your connectors are properly rated to prevent

resistance heat from building up, because that can damage the connector and shorten its lifespan.

For example, if a connector is rated for

20 amps, you want to stay well below that—

usually around 80% of its max—to give yourself some

wiggle room for fluctuations in temperature and insulation quality. Knowing these details isn’t just

about safety; it actually helps your whole system work better, and it can save you some hassle

and money on repairs down the line.

Importance of Wire Gauge Compatibility in Connector Selection

When you're picking auto wire connectors, one of the most important things to keep in mind is making sure they match the wire gauge. You know, the wire gauge basically tells you how thick the wire is, and that really impacts how well your entire system works. Using connectors that fit the wire gauge perfectly helps everything run smoothly — better conductivity, less risk of overheating, and fewer problems with contact resistance. This gets especially crucial in tough applications like military and aerospace stuff, where engineers aren’t just worried about size or weight, but also about cost and how quickly things can get done. Making sure your connectors match the wire gauge can really improve the reliability and overall performance of your electronics, especially when you’re upgrading or retrofitting gear.

Plus, in today’s world where multi-wire power inputs are pretty common, balancing the current is super important. If the wires aren’t gauge-matched properly, you might end up with uneven current flow, which can lead to failures or just mess with performance. So, whenever you’re picking connectors, double-check that they’re compatible with your wire gauge—that way, everything stays running smoothly. Oh, and don’t forget — this whole interplay between wire gauge and connectors isn’t just for electrical systems; it’s also a big deal when it comes to audio setups, where high-quality signal transfer matters a lot. Bottom line? Pay attention to wire gauge compatibility — it’s a key step in making sure your connectors do their job right and your project stays reliable, plain and simple.

Easy Identification: How to Read Connector Specifications and Ratings

When you're choosing the best auto wire connectors and terminals, it’s actually really important to get a good understanding of their specs and ratings. Every connector has its own set of details—like how much voltage and current it can handle, or its temperature limits. Basically, these ratings tell you how much load a connector can take without failing. So, it's super important to match these specs with your vehicle's electrical setup. Always double-check the info on the packaging or the manufacturer's datasheet to make sure it’s a good fit for your project.

A handy tip? Look for connectors that are easy to identify—things like color coding or clear symbols can save you a headache when you're installing or troubleshooting. It makes things way faster when you don’t have to second-guess which connector is which. Also, if you're working in tougher conditions, consider connectors that are waterproof or heat-resistant—that way, they’ll hold up better over time, especially in harsh environments. Paying a little attention to these details can really make a difference in how well your wiring holds up and how long it lasts.

Trends and Innovations in Auto Wire Connectors: What to Look For in 2023

Hey, did you know that in 2023, the world of auto wire connectors is really evolving? There's a lot of exciting stuff happening that anyone into cars should definitely keep an eye on. One of the biggest trends right now is the shift towards using more eco-friendly materials. Manufacturers are now focusing on making connectors from recyclable and sustainable stuff, which is pretty cool because it helps the environment, but also means these connectors are more reliable in different weather conditions. It’s like hitting two birds with one stone!

And here's something else that's pretty intriguing—smart technology is making its way into auto wire connectors. With electric vehicles and all these high-tech features in cars nowadays, connectors are getting some seriously advanced features, like built-in diagnostics and better ways to connect to various systems. These smart connectors basically help different parts of the car talk to each other smoothly, which means better performance and easier troubleshooting when things go wrong. As cars keep getting more complex, I think we're gonna see a bigger demand for these reliable, intelligent connectors—both for manufacturers and us car enthusiasts. It’s quite the leap forward, don’t you think?

7 Essential Tips for Choosing the Best Auto Wire Connectors Terminals - Trends and Innovations in Auto Wire Connectors: What to Look For in 2023

| Tip | Description | Material | Current Rating (A) | Innovations |

|---|---|---|---|---|

| 1. Choose Quality Materials | Select connectors made from high-quality materials to ensure durability. | Copper, PVC | 20A | Corrosion-resistant coatings |

| 2. Check Compatibility | Ensure connectors are compatible with your vehicle's wiring system. | Nylon, Copper | 25A | Universal fit designs |

| 3. Assess Voltage Rating | Choose connectors with the appropriate voltage rating for safety. | Thermoplastic, Brass | 30A | High-voltage options |

| 4. Consider Weather Resistance | Opt for connectors that can withstand various weather conditions. | Silicone, Nylon | 15A | IP-rated connectors |

| 5. Ease of Installation | Choose connectors that are easy to install, saving you time. | Polycarbonate, Copper | 10A | Plug-and-play designs |

| 6. Analyze Size and Fit | Consider the size of connectors to ensure proper fit in tight spaces. | Aluminum, PVC | 12A | Compact designs |

| 7. Price and Warranty | Evaluate the price and warranty for better value. | N/A | N/A | Extended warranties available |

FAQS

: Auto wire connectors should be made from high-quality materials such as copper for conductors and high-grade thermoplastics for insulators, as these can withstand extreme temperatures and resist corrosion.

Connectors made from high-quality materials can last up to 50% longer than those made from lower-quality materials, significantly impacting their durability and performance.

Tin-plated copper connectors exhibit a 30% improvement in resistance to oxidation compared to standard copper connectors, resulting in more reliable connections and reduced maintenance needs.

Wire gauge compatibility is crucial because it affects conductivity and can minimize overheating and contact resistance, enhancing overall performance and reliability.

Mismatched wire gauge can lead to unequal current distribution, which may cause failures or decrease performance, particularly in demanding applications.

Connector specifications can be easily identified by checking the voltage, current capacity, and temperature tolerance indicated on the packaging or manufacturer’s datasheet.

Look for connectors that offer easy identification through color coding or clearly marked symbols, which can help save time during installation and troubleshoot issues quickly.

Yes, connectors designed for specific environments, such as waterproof or heat-resistant models, provide added durability and reliability, making them suitable for extreme conditions.

Ensuring proper wire gauge compatibility can significantly enhance the effectiveness of audio setups by ensuring high-quality signal transmission.

Observing connector specifications attentively ensures better performance and longevity in auto wiring connections, as it helps to match the connector characteristics with the vehicle's electrical systems.

Conclusion

When you're on the hunt for the best auto wire connectors and terminals, it’s really important to understand the different types out there and what they’re best suited for in cars. Knowing what material they’re made of can make a big difference in how long they last, and don’t forget to check their voltage ratings and current capacity—these are key for making sure everything runs safely and smoothly. Also, make sure the wire gauge matches up perfectly; it’s one of those little details that can save you a lot of headache later. Being able to read connector specs easily can also help speed up your decision-making process.

With new trends and tech innovations popping up all the time in 2023, staying in the loop about the latest stuff really pays off. It’ll help you pick out wire connectors that you can trust and that work well. At Yueqing Haidie Electric Co., Ltd., we’re all about offering top-notch wire harness solutions, and we’re proud of our reputation for quality in auto parts. By keeping these tips in mind, you’ll be able to choose auto wire connector terminals that last longer and perform better—making your automotive projects smoother and more reliable.

Related Posts

-

Unleashing the Power of China's Manufacturing with Best Car Wire Plug Innovation

-

5 Key Benefits of Auto Wire Harness in Modern Automotive Manufacturing

-

Exploring Industry Case Studies: The Versatile Use of Best Wire Harness Connectors

-

Exploring Unique Applications and Features of the Best Engine Wiring Harness for Diverse Industries

-

Proudly Made in China Best Elevator Connector for a Global Market

-

Mastering Wire Car Construction Techniques for Optimal Performance and Safety

Blog Tags: