7 Essential Tips for Choosing the Best Auto Wiring Harness: Optimize Your Production with 30% Less Downtime

Table of Contents

- Understanding the Importance of Quality Auto Wiring Harness in Production Efficiency

- Key Factors to Consider When Selecting an Auto Wiring Harness

- How to Analyze Compatibility for Your Specific Automotive Needs

- Best Practices for Installation and Maintenance of Wiring Harnesses

- Cost-Effectiveness: Balancing Quality and Budget in Wiring Harness Selection

- Common Mistakes to Avoid When Choosing an Auto Wiring Harness

- Optimizing Your Vehicle's Performance: The Importance of Quality Wiring Harness Connectors

- FAQS

- Related Posts

You know, in the auto industry these days, everyone’s really feeling the pressure to find wiring harness solutions that are both efficient and reliable. I mean, recent reports are saying the global market for automotive wiring harnesses is set to hit around 72 billion USD by 2025, growing at about 7.1% annually—that’s quite a jump! This growing demand just highlights how important it is for manufacturers to streamline their production and keep downtime to a minimum.

At Yueqing Haidie Electric Co., Ltd., we totally get this trend. That's why we're committed to offering top-notch wiring harness solutions that are tailored to meet the specific needs of auto parts companies. With years of experience under our belt, we've earned a solid reputation for delivering wiring harnesses that are not only reliable but also long-lasting. And honestly, our products have helped businesses cut down operational hiccups by up to 30%.

As the industry keeps changing, it’s super important to understand how to pick the right auto wiring harness—staying ahead of the game and keeping things running smoothly is what it’s all about.

Understanding the Importance of Quality Auto Wiring Harness in Production Efficiency

In the fast-moving world of automotive manufacturing, keeping production efficient is more important than ever. A really well-made auto wiring harness can make a big difference—helping to cut down on downtime and keep things running smoothly. I came across a report from the Automotive Industry Action Group that suggests a properly engineered wiring harness can actually shave up to 15% off the time it takes to assemble a vehicle. That kind of boost is huge, especially when companies are racing to meet the jaw-dropping demand for quicker delivery without sacrificing quality.

On top of that, the reliability and durability of these wiring harnesses play a huge role in keeping operations running without a hitch over the long haul. According to a study published in the International Journal of Automotive Technology, about a quarter of vehicle breakdowns can be linked back to electrical problems—many of which come from wiring harnesses that just aren’t up to scratch. So, investing in high-quality harnesses that can handle everyday use isn’t just about keeping things running smoothly today, but also about making sure your vehicles last longer and stay dependable.

At the end of the day, choosing the right wiring harness isn’t something to overlook — it’s really about protecting your investment in both short-term efficiency and the overall reliability of your vehicles.

Key Factors to Consider When Selecting an Auto Wiring Harness

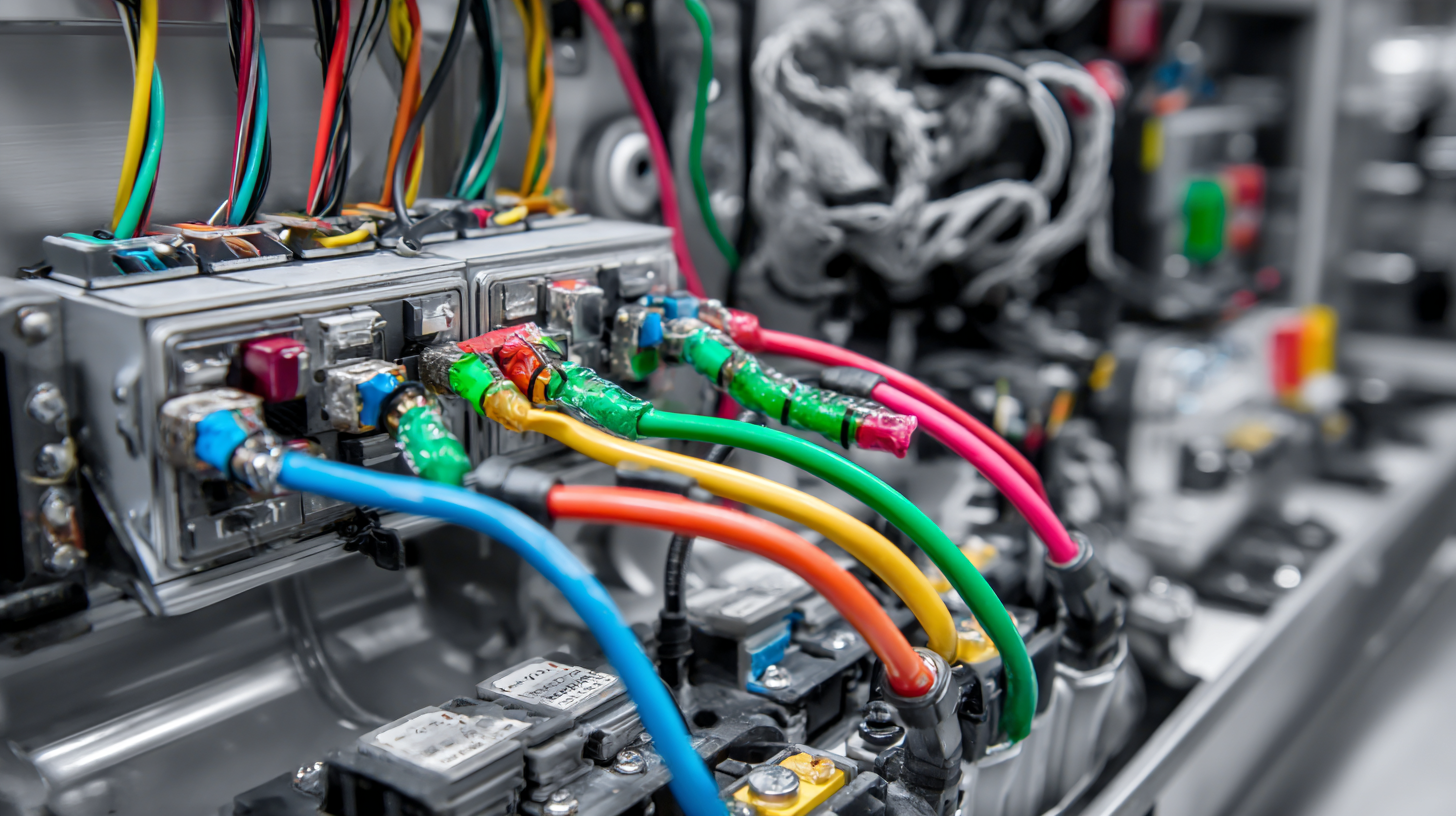

Picking the right auto wiring harness is pretty crucial if you want to keep production smooth and avoid those annoying downtimes in automotive manufacturing. A big part of it is making sure the harness actually matches the vehicle’s electrical setup. With more and more cars going electric these days, manufacturers really need to double-check that their wiring can handle all the advanced tech—it's not just about the basics anymore. In fact, I read somewhere that nearly 40% of auto makers have seen their efficiency go up by choosing harnesses that fit their electrification plans. Pretty neat, huh?

On top of that, the quality of the materials used really makes a difference. Using high-end materials can cut down on maintenance headaches and boost reliability big time. Some industry analysis even suggests that investing a little more upfront in premium wiring parts can reduce overall production costs by as much as 20%. Oh, and don’t forget about connectors and terminals — picking the right ones that hold up under different weather conditions and rough handling is super important too. When you focus on these stuff, it’s way easier for automakers to pick a wiring harness that not only keeps production humming along but also helps make vehicles last longer and perform better overall.

7 Essential Tips for Choosing the Best Auto Wiring Harness

How to Analyze Compatibility for Your Specific Automotive Needs

When you're trying to pick the best auto wiring harness for your car, it's super important to check if everything lines up correctly. Skipping this step can lead to a bunch of headaches later on, like delays or even problems in the long run. I read somewhere recently—like in Automotive Engineering International—that using mismatched wiring parts could boost your assembly time by almost 30%, which is a big deal. So, starting out with compatible components really helps keep things moving smoothly and saves you from unnecessary setbacks.

One thing I’d recommend is taking a good look at the specs of both the wiring harness and your vehicle. Things like gauge size, dielectric strength, and the temperature rating—trust me, even tiny differences can cause major issues down the line. And if possible, go for OEM harnesses that are designed specifically for your car model; that way, you avoid a lot of headaches trying to make incompatible parts fit.

Another tip? Definitely check out product databases or compatibility charts from the manufacturers. They usually have all the latest info about different harness designs and what cars they work with. Using these resources can really help you make smarter choices, which means less downtime and a more efficient build process overall.

Best Practices for Installation and Maintenance of Wiring Harnesses

When you're working on installing and maintaining auto wiring harnesses, sticking to best practices is super important if you want things to run smoothly and reliably. It kinda reminds me of setting up fiber optic cables — doing some careful planning and thinking ahead can really save you a lot of headaches later on. The first thing you should do is figure out exactly what your wiring needs are and pick a harness that fits those specs. Handling the wiring harness properly during installation is a big deal too; you want to avoid sharp bends or kinks because those can cause short circuits or other issues down the line.

Oh, and don’t forget—regular check-ups are key. That means inspecting connectors for any corrosion or wear and tear. If you ignore these signs, it could end up messing with the whole system. It’s also helpful to run standard tests on the wiring to catch problems early before they turn into bigger headaches. By following these simple guidelines, you’ll boost the lifespan and performance of your wiring harness, making sure everything runs smoothly with less downtime — kinda like how data centers keep things ticking efficiently.

Cost-Effectiveness: Balancing Quality and Budget in Wiring Harness Selection

When you're choosing an auto wiring harness, cost is definitely a big deal. You want to find that sweet spot between good quality and sticking to your budget, especially if you're trying to keep production downtime to a minimum. I recently read a report from MarketsandMarkets, and it pointed out that the global market for automotive wiring harnesses is expected to jump from about $60 billion in 2021 to over $82 billion by 2026. That really highlights how much companies are investing in better materials and smarter designs to cut costs. Investing in a dependable wiring harness isn’t just about saving money — it can actually help you streamline operations and cut down on downtime by up to 30%, which is pretty significant.

At Yueqing Haidie Electric Co., Ltd., we're all about providing custom wiring solutions that fit our clients' specific needs. Our focus on quality has really helped us build a solid reputation. Lots of our customers praise how durable and reliable our products are. Having the right wiring harness can make a big difference—reducing the chances of product failures and boosting overall efficiency. As the auto industry keeps evolving, staying ahead with innovative wiring solutions is key to staying competitive — all without breaking the bank.

Common Mistakes to Avoid When Choosing an Auto Wiring Harness

When you're choosing an auto wiring harness, it’s really important to steer clear of some common mistakes—otherwise, your project might not go as smoothly as you’d like. One big thing to watch out for is forgetting to check if the harness actually fits your vehicle’s specifics. Seriously, make sure it’s compatible with your car’s make and model because mismatched parts can cause all sorts of issues like malfunctioning components or just a lot of frustrating downtime.

Another thing folks often overlook is the quality of the materials used in the wiring harness. Going for the cheapest options might save you a buck upfront, but it can backfire in the long run with parts wearing out way too soon, leading to some costly repairs. Look for harnesses that use high-quality wires with solid insulation—stuff that'll handle heat and friction without giving in. Also, don’t forget to check that the connectors are sturdy and resistant to corrosion, especially if you're dealing with rough environments.

Finally, it’s really wise to chat with experts or follow tried-and-true best practices when installing. Poor wiring setup can cause issues like starter problems or even engine failures—definitely not something you want during a race or your everyday commute. Keep these tips in mind, and you’ll not only save yourself some headaches but also make the whole process a lot more efficient and less stressful.

7 Essential Tips for Choosing the Best Auto Wiring Harness

| Tip | Description | Common Mistakes |

|---|---|---|

| Understand Vehicle Specifications | Ensure the harness matches the specific vehicle model and year. | Ignoring compatibility can lead to functional issues. |

| Assess Quality of Materials | Select harnesses made with durable, heat-resistant materials. | Choosing low-quality cables can cause premature failure. |

| Check for Standards Compliance | Ensure the harness complies with industry standards (e.g., SAE, ISO). | Overlooking certifications may affect safety. |

| Evaluate Wiring Layout | Study the layout for easy installation and optimal performance. | A chaotic layout complicates installation and increases downtime. |

| Prioritize Heat and Moisture Resistance | Look for features that protect against extreme conditions. | Neglecting environmental factors can lead to wiring damage. |

| Consult Professionals | Seek advice from expert installers for informed decisions. | Trying to DIY without expertise may result in mistakes. |

| Read Reviews and Testimonials | Examine user feedback for insights on performance and reliability. | Ignoring past user experiences can lead to poor choices. |

Optimizing Your Vehicle's Performance: The Importance of Quality Wiring Harness Connectors

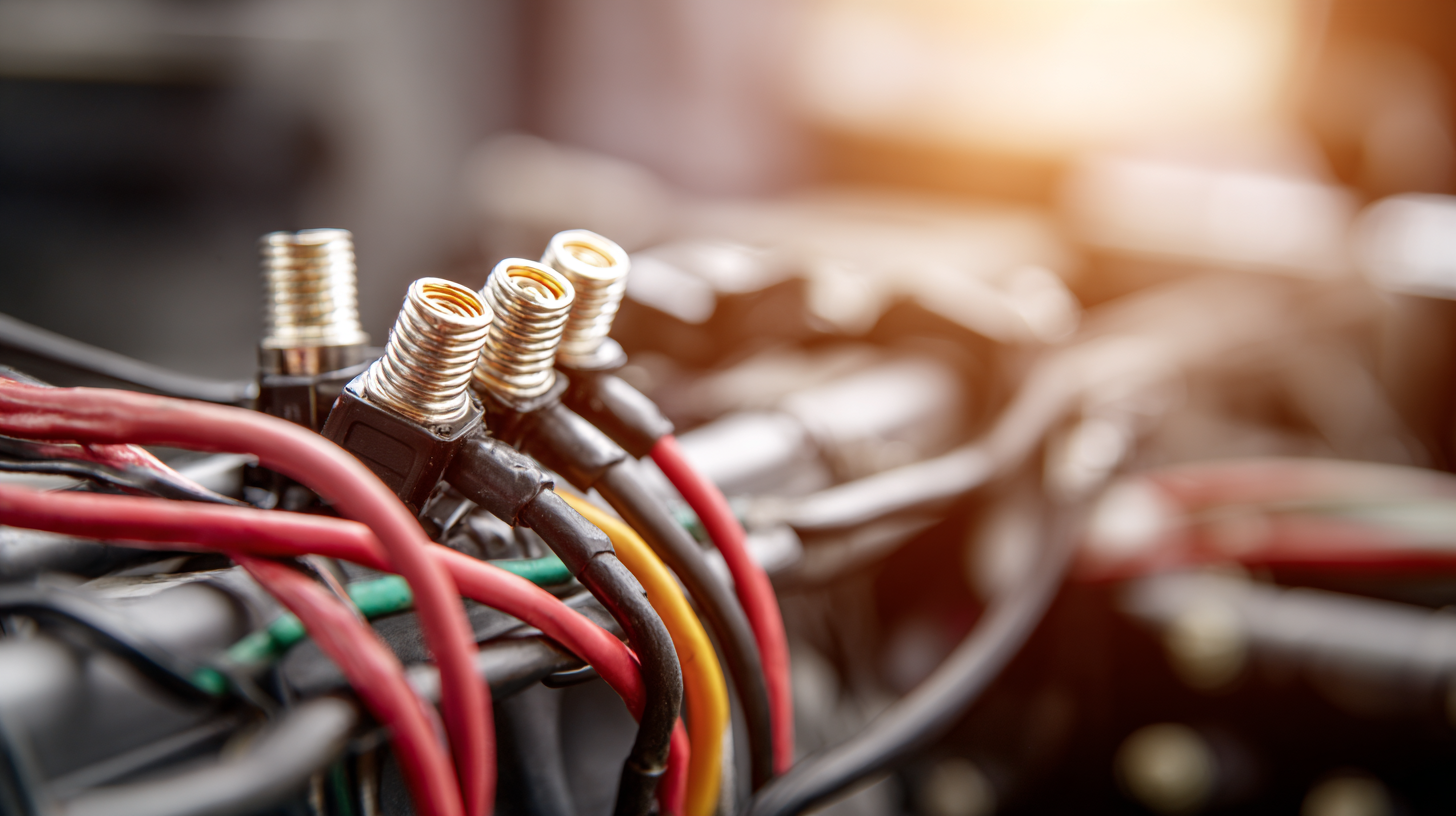

Optimizing the performance of your vehicle goes far beyond just tuning the engine or enhancing aerodynamics. A crucial yet often overlooked aspect is the quality of wiring harness connectors. These connectors serve as the lifelines of your automotive electrical systems, ensuring seamless communication between various components. According to a report from Automotive News, poor connections can lead to failures in critical systems, potentially causing performance issues and safety hazards.

When selecting wiring harness connectors, it's essential to prioritize quality over cost. The use of high-grade materials can significantly reduce the risk of connection failures. For example, the **22pin Auto Connecting Crimp Type Stamping Female Wire Crimp Terminal (2-1823440-3)** exemplifies an effective choice. Designed for durability and reliability, this connector enables robust connections that withstand the rigors of automotive applications. Industry studies show that connectors like these can enhance the overall reliability of electrical systems by as much as 30%, translating to improved performance and longevity for your vehicle.

Furthermore, a comprehensive analysis by the Society of Automotive Engineers highlights that vehicles with optimized wiring systems experience fewer electrical-related breakdowns. By investing in quality wiring harness connectors, such as the 2-1823440-3 model, vehicle owners can reduce maintenance costs while significantly enhancing the reliability of their automotive performance. This investment in reliable connectors ultimately leads to a smoother driving experience, making it a critical consideration for any vehicle optimization effort.

FAQS

: Selecting the right auto wiring harness is essential for optimizing production and minimizing downtime in automotive manufacturing, especially with growing vehicle electrification.

Compatibility ensures that the wiring harness can support advanced electric systems, which is crucial for manufacturers looking to meet electrification goals.

High-quality materials are critical as they reduce maintenance costs and enhance reliability, resulting in better overall production costs.

Investing in premium harness materials can lead to up to a 20% decrease in overall production costs and increased production efficiency.

Connectors and terminals should be evaluated for optimal performance and durability, especially under varying environmental conditions, to ensure reliability.

The global automotive wiring harness market is projected to grow from $59.9 billion in 2021 to $82.5 billion by 2026.

Investing in a reliable wiring harness can optimize operations and reduce potential downtime by up to 30%.

Cost-effectiveness is crucial as manufacturers must balance quality with budget constraints to avoid delays and inefficiencies in production.

Yueqing Haidie Electric Co., Ltd. provides tailored wire harness solutions that meet the unique needs of clients, focusing on quality and reliability.

As the automotive industry evolves, innovative wiring solutions are key to maintaining a competitive edge while managing budget constraints.

Related Posts

-

7 Essential Tips for Choosing the Best Delphi Connector for Your Needs

-

Ultimate Guide to Comparing the Top Automotive Plug Connectors on the Market

-

Comprehensive Guide to Best Wire Connecters with Technical Specifications and Installation Tips

-

Benefits of Choosing the Best Car Pigtail for Enhanced Vehicle Performance

-

Unleash Global Sourcing Power with Premium Circuit Board Wire Terminals from Top Chinese Manufacturers

-

Exploring Unique Applications and Features of the Best Engine Wiring Harness for Diverse Industries

Blog Tags: