5 Key Benefits of Auto Wire Harness in Modern Automotive Manufacturing

Table of Contents

- Understanding the Role of Auto Wire Harness in Modern Vehicles

- Exploring the Cost-Efficiency of Using Wire Harness Systems

- How Auto Wire Harness Enhances Vehicle Safety and Reliability

- The Impact of Wire Harness on Automotive Design Flexibility

- Innovative Materials and Technologies in Auto Wire Harness Manufacturing

- Comparing Traditional Wiring Methods to Modern Wire Harness Solutions

- Enhancing Your Automotive Projects with the 52 PIN FEMALE 7182-5055-40 Wire Harness Connector

- FAQS

- Conclusion

- Related Posts

Hey there! So, in today’s fast-moving world of cars, it’s pretty clear that auto wire harnesses are more important than ever. As vehicles get smarter and packed with more complex electrical systems—plus the push for better performance—these harnesses are really the backbone that keeps everything running smoothly. I recently saw a report from ResearchAndMarkets saying the global auto wire harness market might hit a whopping USD 76 billion by 2025, mainly thanks to the surge in electric and hybrid cars.

Hey there! So, in today’s fast-moving world of cars, it’s pretty clear that auto wire harnesses are more important than ever. As vehicles get smarter and packed with more complex electrical systems—plus the push for better performance—these harnesses are really the backbone that keeps everything running smoothly. I recently saw a report from ResearchAndMarkets saying the global auto wire harness market might hit a whopping USD 76 billion by 2025, mainly thanks to the surge in electric and hybrid cars.

Over at Yueqing Haidie Electric Co., Ltd., we’re right in the middle of all this change, crafting customized wire harness solutions to meet what car makers need these days. Our focus on top-notch quality has earned us quite a few fans behind the scenes, helping us build a solid reputation in this space. In this blog, I’ll walk you through five key benefits of auto wire harnesses — how they’re truly transforming modern car manufacturing and making everything a lot more reliable and efficient.

Understanding the Role of Auto Wire Harness in Modern Vehicles

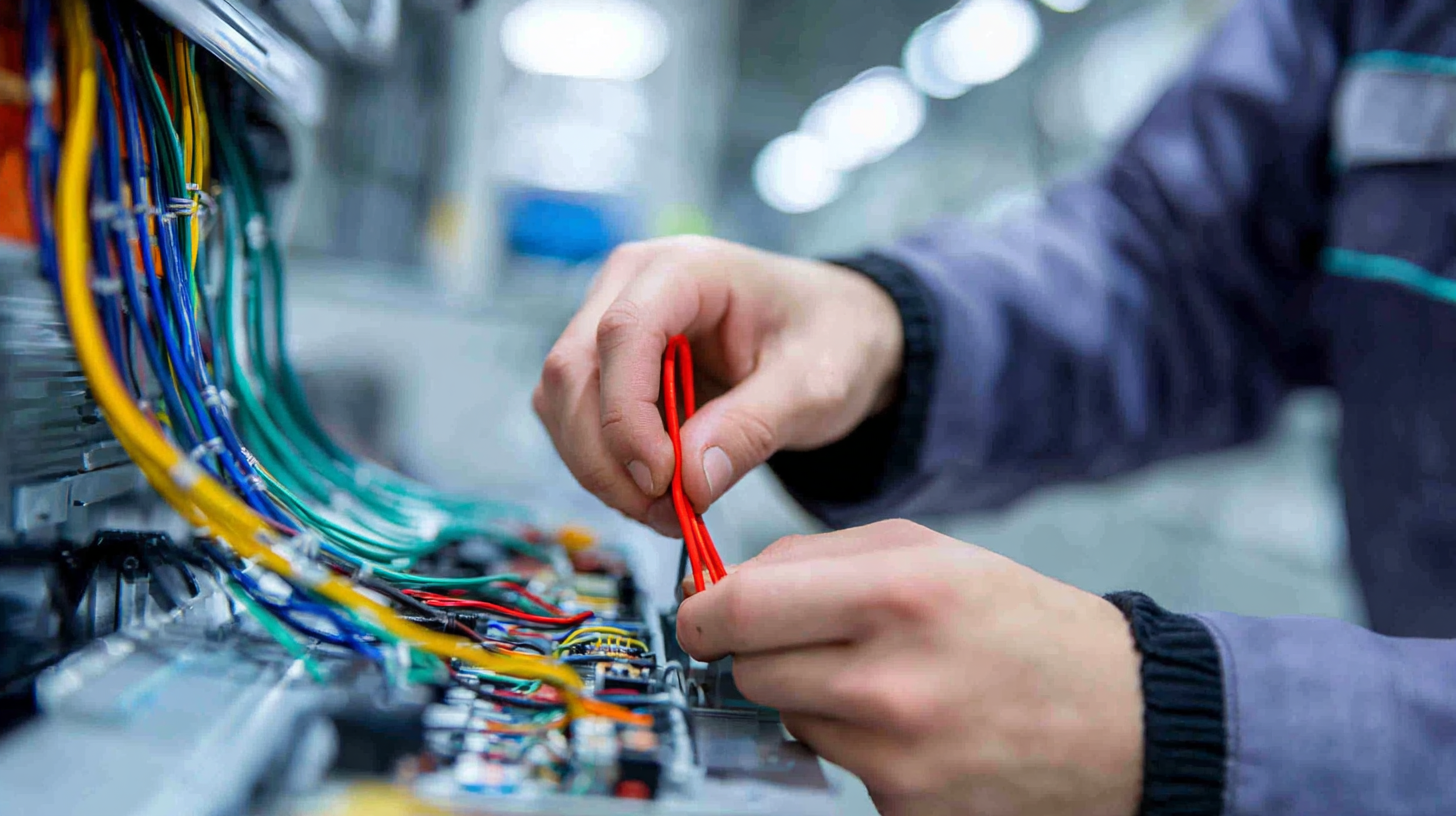

You know, in today's cars, the auto wire harness is kinda like the car's nervous system. It might not be something you think about every day, but it’s responsible for connecting all the electrical parts and making sure everything runs smoothly. From helping the engine, transmission, and even entertainment systems talk to each other, these harnesses are super important for keeping your car working well and making your drive a better experience. Honestly, a good wire harness can really make a difference.

When you're picking out a wire harness for your ride, it's a good idea to think about what your car needs—both now and down the road. Modern cars, especially electric ones or those packed with fancy safety tech, need harnesses that can handle future upgrades. Getting it right the first time means your setup will last longer and be more reliable.

And here’s a bonus — having a solid wire harness isn't just about convenience, it actually makes your car safer. Why? Well, it cuts down on a mess of wires and lowers the chances of electrical issues. Plus, most of these harnesses are designed with insulation and protective layers to stop short circuits and keep things protected against rough weather or other harsh conditions.

A tip: Don’t forget to check on your wiring now and then. Doing some regular maintenance or inspections can really save you from big repairs later on. Plus, it helps keep all your electrical systems working smoothly, which isn’t just good for your car's lifespan but also your safety. So yeah, a little TLC on those wires goes a long way.

Exploring the Cost-Efficiency of Using Wire Harness Systems

In today’s highly competitive world of car manufacturing, saving costs is a big deal. One pretty cool solution that’s been gaining traction is auto wire harness systems. Basically, they make it easier to connect all those electrical parts inside a vehicle— saving time and cutting down on the manual labor needed during assembly. Instead of dealing with a tangled mess of wires, you get one neat, organized harness. That means fewer mistakes and a smoother, faster production line.

Plus, these wire harness systems help save money overall by making the supply chain more efficient. Buying pre-assembled harnesses in large quantities means companies can get better deals and lower the cost for each unit. It also frees up space since inventory costs go down, and it speeds up manufacturing, helping companies hit their deadlines more easily. Down the line, investing in auto wire harnesses isn’t just smart—it’s a move that can really boost efficiency and improve profits in the long run.

How Auto Wire Harness Enhances Vehicle Safety and Reliability

In today's car industry, integrating auto wire harnesses has really made vehicles safer and more reliable. These critical parts connect all the electronic systems smoothly—think about features like advanced driver-assistance systems (ADAS) and other safety tech. By organizing and securing the wiring properly, auto wire harnesses cut down on the chances of electrical issues, which, if they happen, could lead to serious accidents. Honestly, the reliability of these harnesses is pretty much tied to how safe the vehicle is overall, so you can see why they’re such a must-have in modern car design.

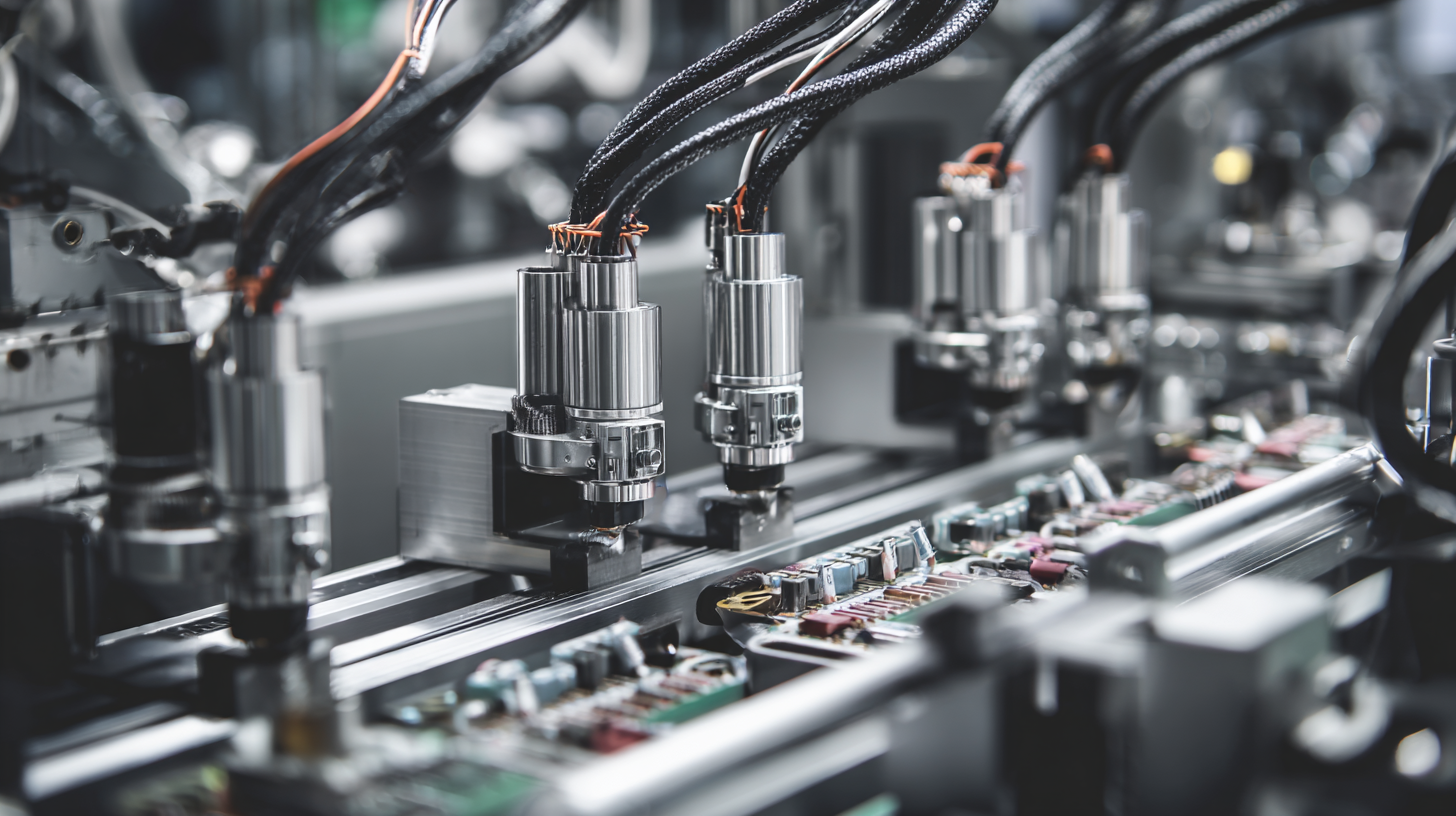

And get this—one of the coolest advances in automotive wiring tech is the use of fiber optics. These allow for super fast data transfer, which supports all kinds of complex systems in modern cars, like the Media Oriented Systems Transport (MOST) network that handles in-car entertainment and communication. As more vehicles shift towards electric and hybrid setups, the need for efficient data management gets even more important. Plus, fiber optics are great because they help lighten the wiring, making the whole system more responsive and performant. This kind of innovation doesn’t just boost safety; it also keeps vehicles packed with the latest tech features. Basically, automakers are making sure we get cars that are not only safer but also brimming with cutting-edge technology that we expect nowadays.

The Impact of Wire Harness on Automotive Design Flexibility

You know, with the rise of auto wire harness technology, things in automotive design got a lot more flexible. Manufacturers can now think outside the box when it comes to how they set up vehicle layouts and add new features. Basically, by organizing all those complex electrical systems into a streamlined harness, they can save space and cut down on weight—pretty crucial when you're trying to make cars more efficient. This kind of flexibility really opens the door for adding cool stuff like

fancy infotainment systems or advanced driver-assist features, which are super important in today’s competitive car market.

When you're designing a vehicle, it's probably wise to think about how the wire harness can adapt as new technologies come along. Going for modular designs is a smart move because it makes upgrades easier down the line, without needing to tear everything apart. Not only does this make the car last longer and stay relevant, but it also helps manufacturers respond faster to what consumers want.

Plus, teaming up closely with wire harness suppliers early in the design process can be a game changer. They often have the latest materials and tech insights that can lead to innovative wiring solutions. These partnerships don’t just boost flexibility—they can really amp up overall vehicle performance and dependability. Basically, working together like this helps make sure the final design is ready for today’s trends and future innovations alike.

Innovative Materials and Technologies in Auto Wire Harness Manufacturing

The automotive world is going through some pretty exciting changes right now, mainly thanks to the new materials and tech being used in designing auto wire harnesses. You know, these harnesses are basically the backbone of all the electrical connections in cars, so they’re super important for making sure everything runs smoothly and reliably. Recent industry reports show that the global market for wiring harnesses in trains, for example, is expected to jump from around $4.15 billion in 2025 to about $6.64 billion in the next few years. That’s part of a bigger trend in the auto industry, where connectivity and automation are becoming bigger than ever.

What’s really cool is how newer materials like lightweight composites and high-performance insulations are changing the game. These innovations are not only helping to cut down the weight of vehicles — which is a big plus for fuel efficiency — but they also boost durability and resistance against the elements. Plus, incorporating smart tech like sensors and IoT gadgets right into the wiring harnesses is opening up a whole new world of smarter, more connected vehicles. As manufacturers keep pushing forward with these upgrades, it feels like the humble wire harness is about to take on a really central role in shaping the future of cars — pretty amazing, right?

Comparing Traditional Wiring Methods to Modern Wire Harness Solutions

When it comes to building cars, traditional wiring methods have pretty much been the norm for connecting all those electronic parts. Honestly, it can get pretty messy—tons of wires tangled up, making installation a real headache, and sometimes mistakes happen more often than you'd like. But nowadays, new wire harness tech has totally changed the game. These harnesses group all the wires together into a single, neat bundle, which not only cuts down on the clutter but also makes putting everything in much easier. It’s a game-changer for manufacturers because it speeds things up and boosts quality—something really important given how fierce the auto industry is these days.

Looking at the difference between old-school wiring and these modern harnesses really shows why making the switch makes sense. Not only do these harnesses organize the electrical system way better, but they also help keep the weight down, which means better fuel economy for the car. Plus, they’re built tough—resistant to vibrations and rough weather—so they last longer and stay reliable over time. Moving to wire harnesses really demonstrates how embracing new technology can make car manufacturing smarter, more efficient, and even a bit greener. Pretty cool, right?

5 Key Benefits of Auto Wire Harness in Modern Automotive Manufacturing

Enhancing Your Automotive Projects with the 52 PIN FEMALE 7182-5055-40 Wire Harness Connector

Enhancing automotive projects requires the right components, and one standout option is the 52 PIN FEMALE 7182-5055-40 Wire Harness Connector. This connector is designed to streamline connections and ensure reliability in various automotive applications. With its crimp-type design, it provides excellent electrical connectivity while allowing for easy installation and maintenance.

The 52 pin Auto Connecting Crimp Type Stamping Female Wire Crimp Terminal 7182-5055-40 is particularly notable for its durability and versatility. Made from high-quality materials, it withstands the rigors of the automotive environment, ensuring that your projects not only meet but exceed industry standards. Its ability to handle multiple connections in a compact form factor makes it ideal for deploying in vehicles where space is at a premium.

Integrating this connector into your automotive projects can lead to improved performance and a more organized wiring system. Whether you’re working on a custom car build, retrofitting older models, or enhancing vehicle electronics, the 7182-5055-40 wire harness connector stands out as an essential tool in achieving a professional finish and reliable operation.

FAQS

: Auto wire harness systems are organized bundles of wires that connect various electrical components in vehicles. They streamline assembly processes, reduce labor costs, minimize errors, and enhance production line productivity.

Wire harness systems allow manufacturers to use pre-assembled harnesses, enabling bulk material purchases and lowering per-unit costs. This reduces inventory expenses and accelerates the manufacturing process.

Wire harness technology allows manufacturers to streamline electrical systems, which helps in allocating space efficiently and reducing vehicle weight, thus enabling easier integration of advanced technologies.

Manufacturers should focus on creating modular designs that can accommodate future upgrades without extensive re-engineering to enhance product longevity and responsiveness to consumer demands.

Collaborating with wire harness suppliers can provide insights into the latest materials and technologies, resulting in innovative solutions that improve design flexibility and overall vehicle performance.

The industry is utilizing lightweight composites and high-performance insulation materials, which reduce vehicle weight, improve fuel efficiency, and enhance the durability of wire harnesses.

Smart technologies, such as sensors and IoT devices, are being integrated into wire harnesses, paving the way for smarter and more connected vehicles.

The global railway wiring harness market is expected to grow from $4.15 billion in 2025 to approximately $6.64 billion in the following years, reflecting a trend towards enhanced connectivity and automation in the automotive sector.

Investing in auto wire harnesses enhances operational efficiency, reduces costs, and improves the ability to meet production deadlines, proving to be a strategic move for manufacturers.

Innovative wire harness technologies enhance reliability, efficiency, and adaptability of modern automotive systems, ultimately contributing to better vehicle performance and customer satisfaction.

Conclusion

Nowadays, when it comes to making cars, the Auto Wire Harness is pretty much a game-changer. It’s a central piece that helps organize all the electrical connections, making the whole process smoother and more cost-effective than old-school wiring setups. Plus, with the latest materials and clever tech used in creating these harnesses, you get a boost in safety and reliability—things that really matter in today’s vehicles. It’s all about making cars safer, smarter, and more efficient.

At Yueqing Haidie Electric Co., Ltd., we’re proud to specialize in high-quality wire harness solutions tailored specifically for the automotive world. Our reputation for top-notch products and happy customers really speaks to our dedication. We aim to support the ongoing evolution of car design, always keeping safety and efficiency front and center. Basically, we’re all about helping make your vehicles better, safer, and more reliable—just the way they should be.

Related Posts

-

Exploring Unique Applications and Features of the Best Engine Wiring Harness for Diverse Industries

-

The Definitive Guide to Choosing the Best Automotive Circuit Connectors for Maximum Performance

-

Unleashing the Power of China's Manufacturing with Best Car Wire Plug Innovation

-

Comprehensive Guide to Best Wire Connecters with Technical Specifications and Installation Tips

-

Innovative Solutions for Optimal Wire Connecters Performance

-

7 Proven Benefits of Choosing the Best Connector Housing for Your Needs

Blog Tags: