Mastering Wire Car Construction Techniques for Optimal Performance and Safety

Table of Contents

- Understanding the Basics of Wire Car Design and Construction

- Essential Tools and Materials for Building High-Performance Wire Cars

- Step-by-Step Guide to Wire Car Assembly: Techniques for Success

- Safety Measures Every Wire Car Builder Should Know

- Optimizing Wire Car Performance: Tips and Tricks for Improvement

- Common Mistakes in Wire Car Construction and How to Avoid Them

- Enhancing Automotive Connectivity: The Benefits of the 52 PIN FEMALE 7182-5055-40 Wire Harness Connector

- FAQS

- Related Posts

In today’s constantly changing world of automotive manufacturing, getting a handle on wire car construction techniques is pretty important—don’t overlook it! A report from the International Wire & Cable Conference suggests that the global wire harness market could hit around $30 billion by 2025. That just shows how vital these components are when it comes to vehicle safety and performance. As cars get more and more high-tech, relying on complex electrical systems, having top-notch wire harness solutions isn’t just a bonus anymore — it’s a must.

Yueqing Haidie Electric Co., Ltd. is actually leading the pack in this field. They’re known for delivering outstanding wire harness solutions that fit a bunch of different automotive needs. Thanks to their focus on quality and innovation, they’ve gained a solid reputation and a lot of praise in the industry. In this blog, I want to take a closer look at some of the advanced techniques used in wire car construction—stuff that really helps ensure your vehicle runs safely and performs at its best today.

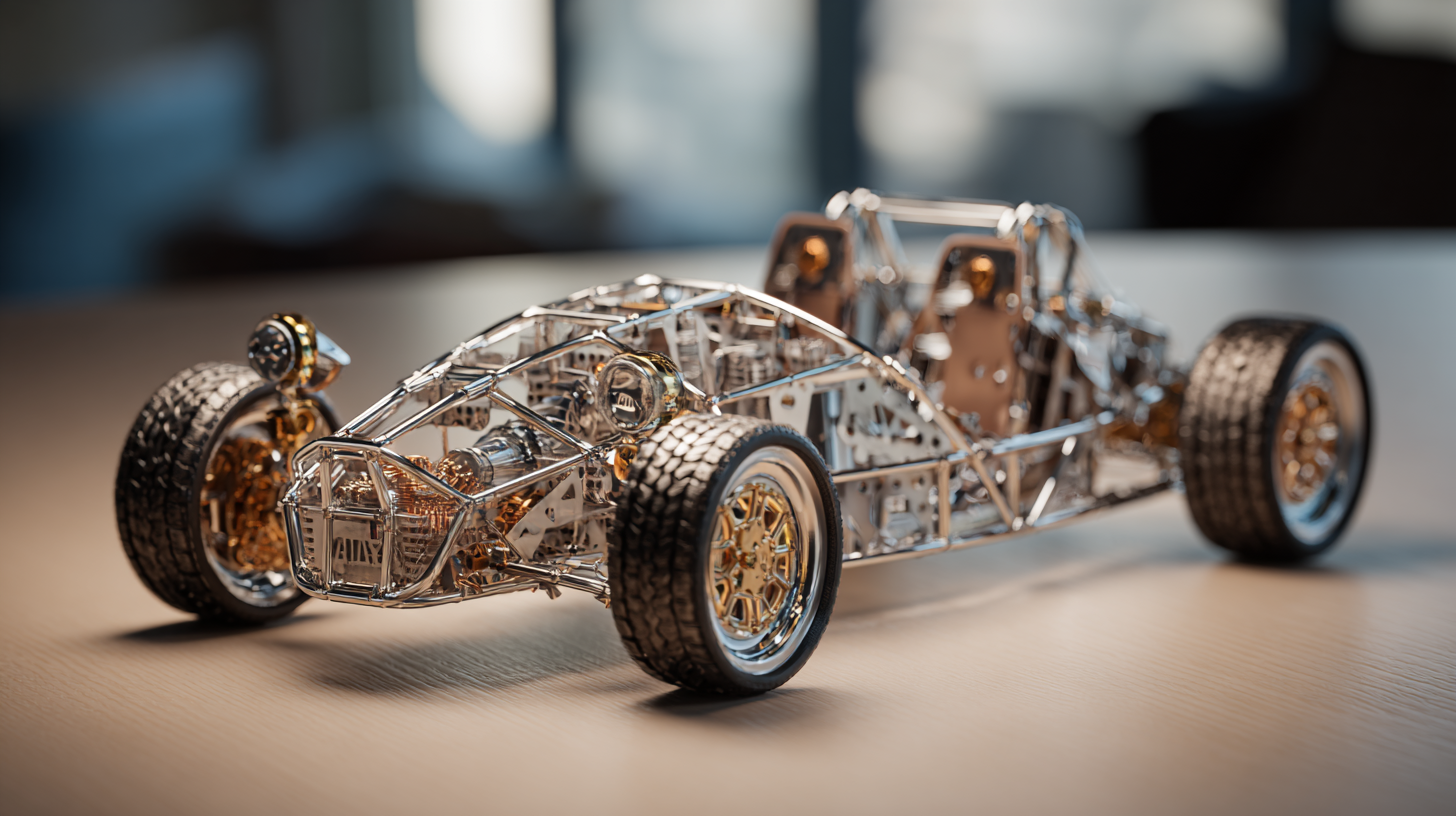

Understanding the Basics of Wire Car Design and Construction

Building a wire car isn’t just about throwing some wires together — you really need a good grasp of the basic design and how everything fits. Since wire cars are often made from lightweight stuff, you have to plan carefully so that your car isn’t just fast but also sturdy enough to handle some rough treatment and outdoor conditions. Finding that sweet spot between being light enough to go fast and strong enough to last is super important. A well-made wire car should be sleek and speedy but still durable enough to survive the bumps and scrapes along the way.

Now, when we talk about safety, especially with electric vehicles (EVs) becoming more common, it’s a good idea to get the hang of how modern vehicles are built. Wire cars can actually reflect some of the complexities you see in real cars — with many parts working together in tricky ways. Knowing about potential risks, like fire hazards linked to battery systems in EVs, can give you a head start in making safer designs. This kind of knowledge not only helps you build better but also gets you ready for any surprise problems that might pop up while you’re using your car. Taking these safety tips to heart will help you create wire cars that are not just cool and fast, but safe and reliable too.

Mastering Wire Car Construction Techniques for Optimal Performance and Safety

| Technique | Description | Materials Used | Safety Considerations | Performance Impact |

|---|---|---|---|---|

| Wire Bending | Techniques for creating precise shapes and angles in wire. | Steel wire, aluminum wire | Use gloves; ensure proper eye protection. | Improves aerodynamics and stability. |

| Wire Joining | Methods for securely attaching different wire components. | Soldering iron, wire connectors | Ensure proper ventilation; avoid burns. | Ensures structural integrity and longevity. |

| Weight Distribution | Techniques to evenly distribute weight for balanced performance. | Different wire gauges, counterweights | Check for stability before use. | Enhances speed and maneuverability. |

| Surface Finishing | Applying finishes to minimize drag and corrosion. | Paint, powder coating | Ensure non-toxic materials are used. | Improves durability and performance. |

Essential Tools and Materials for Building High-Performance Wire Cars

When you're working on building high-performance wire cars, having the right tools and materials is pretty much essential if you want to get the best results. I came across a recent report from the International Association of Wire Forming and Fabrication that mentioned using specialized wire bending and cutting tools can actually boost your precision by up to 30%. Things like good quality wire cutters, benders, and pliers really make a difference—they help you cut each piece exactly right, which is key for making a car that performs well.

On top of that, choosing the right kind of wire is super important too, especially when it comes to safety and how well the car works. According to standards from ASTM International, using high-strength stainless steel or titanium wire can really up the durability and cut down on the chances of your wire bending or warping under stress. Not only does that make your wire car safer to race or test, but it also gives it a nicer, more polished look when you’re done. So, if you focus on getting good tools and solid materials, you’ll end up with a wire car that’s not only a beast in performance but also safe and sleek—all pretty important points to keep in mind.

Step-by-Step Guide to Wire Car Assembly: Techniques for Success

Building a wire car can actually be a pretty exciting project — it’s a fun mix of creativity and engineering all rolled into one. In this guide, I’ll walk you through some key tips to help you put your wire car together successfully. The goal is to make sure it works really well and also meets safety standards, so you can enjoy your build without worries. First things first: gather some good-quality materials. You’ll want sturdy wire, light but strong parts, and reliable wheels. Trust me, using quality stuff not only makes your car last longer but also performs better. Take your time choosing materials that match your design dreams.

Once you've got everything you need, start sketching out your wire car’s design. A solid frame is super important, so plan your wire layout carefully. Begin with the chassis — make sure it’s symmetrical and balanced. You’ll probably find it helpful to twist and bend the wire a bit to create a sturdy base. When attaching the wheels, double-check they’re securely connected and spin freely — that’s what’ll keep your car running smoothly. Also, pay close attention to the connection points because these tend to be the weak spots. By following these steps and tips, you’ll end up with a wire car that’s both functional and safe — a great foundation for whatever projects you want to try next!

Safety Measures Every Wire Car Builder Should Know

So, when you're building wire cars, safety really should be front and center. Did you know that the automotive industry has found that nearly 20% of vehicle problems come down to bad wiring? That just goes to show how important it is to get the construction right. Here at Yueqing Haidie Electric Co., Ltd., we’re all about providing top-notch wire harness solutions, but more than anything, we stress the need to stick to safety protocols during the build. Things like using insulated tools, making sure all connections are tightly secured to avoid short circuits, and regularly checking the wiring for any signs of wear or damage — they’re all essential.

Also, a little tip for anyone into building these wire cars: understanding circuit design is a game-changer. Recent studies show that a well-designed wire harness can boost your vehicle’s performance by up to 15%, mainly by cutting down electrical resistance. Picking the right gauge wire and the right type of insulation can really make a difference, not just for safety but also for how well everything works. As we continue to provide the best wire harness solutions for automotive projects, our main focus stays on safety and performance. So, if you follow these safety tips and pay attention to proper wiring, you’ll not only get better results but also keep risks at bay and build something you can truly be proud of.

Optimizing Wire Car Performance: Tips and Tricks for Improvement

When you're trying to get the best performance out of a wire car, it's super important to really get the basics down — like the design and choosing the right materials. Lately, industry insights have shown that using lightweight but tough materials can actually boost speed and efficiency. For example, I came across a report from the American Society of Mechanical Engineers that says if you build your wire car with high-tensile strength wires, you could see up to 15% improvements in both speed and how efficiently it uses energy. Picking the right wire gauge carefully helps cut down on drag and makes the car more aerodynamic, which is a big deal.

On top of that, tuning the structure of the wire car totally makes a difference. The folks over at the Automotive Engineering Journal point out that tweaking the shape — like improving the curves of the body — can cut air resistance by as much as 20%. Small tweaks, like adjusting the weight distribution and body curvature, can really boost stability and how well the car handles. And honestly, the more you test and tweak based on what you observe in performance, the better your results. It’s all about finding those little improvements that push your car to deliver great speed, while still keeping safety in check.

Optimizing Wire Car Performance: Key Techniques and Safety Measures

This chart illustrates the performance metrics of various wire car construction techniques, showcasing the balance between optimal performance and safety measures.

Common Mistakes in Wire Car Construction and How to Avoid Them

Building wire cars isn't exactly a walk in the park — even the smallest mistake can mess up how well it runs or, worse, compromise safety. One thing folks often overlook is how crucial it is to pick the right materials. Using wires that are too thin or flimsy can make the whole thing pretty fragile. So, it’s always a good idea to choose sturdy, load-appropriate materials to keep everything durable.

Another common issue? Improper weight distribution. A lot of beginners just toss heavier parts wherever without a second thought, and that messes with the car’s balance and stability. To get it right, plan out the layout beforehand — put the heavier bits closer to the center and spread things out evenly across the chassis. Trust me, this small tweak can make your car much easier to handle and reduce the chances of it tipping over.

And don’t forget about testing — it’s something too many people skip. Not trying out the car before you race it can hide problems that could end up being serious safety hazards. Take the time for proper testing, and watch how it performs in different conditions. Make adjustments as needed based on what you see. Honestly, taking these steps can really boost both the safety and performance of your wire car — so it’s worth the effort.

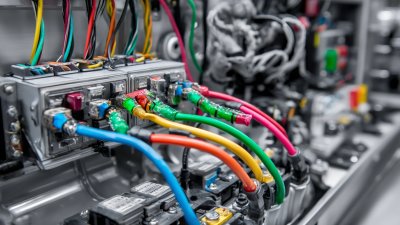

Enhancing Automotive Connectivity: The Benefits of the 52 PIN FEMALE 7182-5055-40 Wire Harness Connector

In the rapidly evolving automotive industry, enhancing connectivity is paramount for the seamless integration of advanced technologies. The 52 PIN FEMALE 7182-5055-40 Wire Harness Connector stands out as a crucial component in achieving this enhanced connectivity. Designed for durability and reliability, this connector facilitates efficient communication between various electronic systems within a vehicle, ensuring that critical functions operate smoothly.

The 52 pin Auto Connecting Crimp Type Stamping Female Wire Crimp Terminal 7182-5055-40 is particularly noteworthy for its robust design and ease of installation. Its crimp-type mechanism allows for secure connections, minimizing the risk of signal loss or interference. This feature is vital in today's vehicles, which increasingly rely on electronic components for features such as advanced driver-assistance systems (ADAS), infotainment, and more. By utilizing this connector, manufacturers can enhance the performance and longevity of their automotive electronics, paving the way for a more interconnected driving experience.

Moreover, the 52 PIN configuration supports the growing demand for high-density connections in modern vehicles. As vehicles evolve with greater complexity, the need for connectors that can handle multiple signals without compromising on size or performance becomes ever more critical. The 7182-5055-40 excels in this pursuit, making it an ideal choice for automotive manufacturers looking to push the boundaries of connectivity while ensuring that all electronic components work in perfect harmony.

FAQS

: Essential tools include high-quality wire cutters, benders, and pliers that improve precision and ensure each piece is cut to the exact specifications needed for optimal performance.

It is recommended to use high-strength stainless steel or titanium wire, as these materials enhance durability and reduce the risk of deformation under stress.

Careful planning of the wire car structure ensures a solid and balanced framework, which is crucial for the overall stability and performance of the wire car.

Safety measures include using insulated tools, securing all connections to prevent short circuits, and regularly inspecting the wiring for wear and tear.

Well-designed wire harnesses can improve vehicle performance by reducing electrical resistance, with proper gauge selection and insulation material playing key roles.

Improper wiring practices account for nearly 20% of vehicle failures, highlighting the need for mastering construction techniques and following safety protocols.

High-quality wire materials not only improve performance but also enhance the overall aesthetic appeal of the final wire car product.

Connection points are often weak spots in the assembly, so ensuring they are securely attached and functioning properly is vital for smooth performance.

The chassis provides the foundational structure of the wire car; ensuring it is symmetrical and balanced is essential for stability and performance.

Builders should securely attach the wheels and ensure they rotate freely, as this is key to achieving smooth performance in the wire car.

Related Posts

-

How to Choose the Best Connector Housing for Your Global Sourcing Needs

-

Exploring Unique Alternatives to Best Automotive Crimp Connectors for Your Projects

-

Ultimate Guide to Choosing the Best Connecting Pin for Optimal Performance in Your Industry

-

7 Proven Benefits of Choosing the Best Connector Housing for Your Needs

-

Top Quality Vehicle Wiring Connectors from a Leading Chinese Manufacturer

-

7 Essential Tips for Choosing the Best Auto Wiring Harness: Optimize Your Production with 30% Less Downtime

Blog Tags: