Mastering Wired Connectors A Step by Step Guide for Beginners

Table of Contents

- Understanding the Basics of Wired Connectors for Beginners

- Types of Wired Connectors: A Comprehensive Overview

- Essential Tools Needed for Wiring Projects

- Step-by-Step Instructions for Making Wired Connections

- Common Mistakes to Avoid When Using Wired Connectors

- Safety Tips and Best Practices for Wired Connector Use

- Exploring the Versatility and Benefits of the PIN HD026-2-11E Male Unsealed Automotive Wire Harness Connector

- FAQS

- Conclusion

- Related Posts

In today’s world, where everything's pretty much connected all the time, having a good handle on wired connectors is a must, especially if you’re thinking about diving into wiring solutions. Here at Yueqing Haidie Electric Co., Ltd., we take pride in our expertise in creating wire harness solutions tailored for the auto parts industry. We’re all about quality, and that’s earned us the trust and good word of lots of customers—so much so that some of our brands have even spun off from that. If you're new to this whole wired connector thing, don’t worry—we’ve put together a simple guide for you. It covers everything from the basic lingo to how to install these connectors properly. Get a grasp on these key parts, and you’ll be able to make reliable connections that keep your projects running smoothly—whether it’s for cars or other industries. Join us as we break down this important topic and give you the tools to get started confidently with wired connectors.

Understanding the Basics of Wired Connectors for Beginners

When you’re diving into the world of electronics, wired connectors are kinda like the unsung heroes that keep everything connected reliably. If you're just starting out with DIY projects or troubleshooting gadgets, getting a handle on the basics of these connectors is a really good idea. Basically, wired connectors are what make sure electrical signals and power can flow smoothly between cables and devices. You’ve probably seen some common ones like USB, HDMI, and Ethernet jacks — each of them designed for specific tasks, and it’s good to know what they’re built for.

The first thing to do is get familiar with the different types and what they’re used for. Take USBs, for example — they’re everywhere these days, used for charging stuff and transferring data. HDMI connectors are super important when it comes to sending high-def video and sound, especially between things like your TV and computer. And, honestly, knowing how to connect and disconnect these properly is key — you don’t wanna damage anything by forcing it or pulling at the wrong angle.

Once you’ve got the basics down about how they work and what they look like, you’ll probably feel a lot more confident handling wired connections. It’s a fundamental part of working with electronics, no matter if you’re just tinkering for fun or getting serious about building something cool.

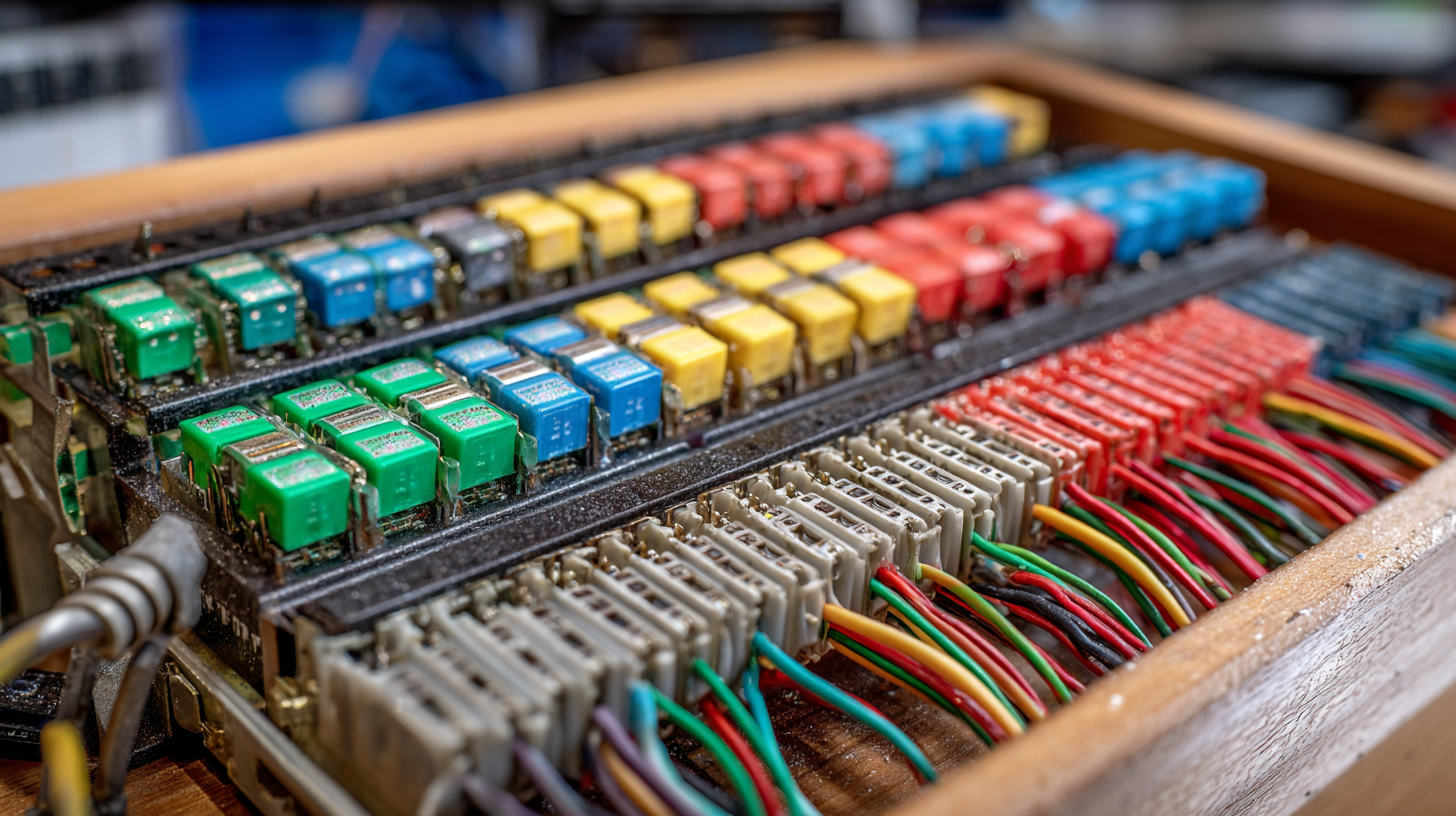

Types of Wired Connectors: A Comprehensive Overview

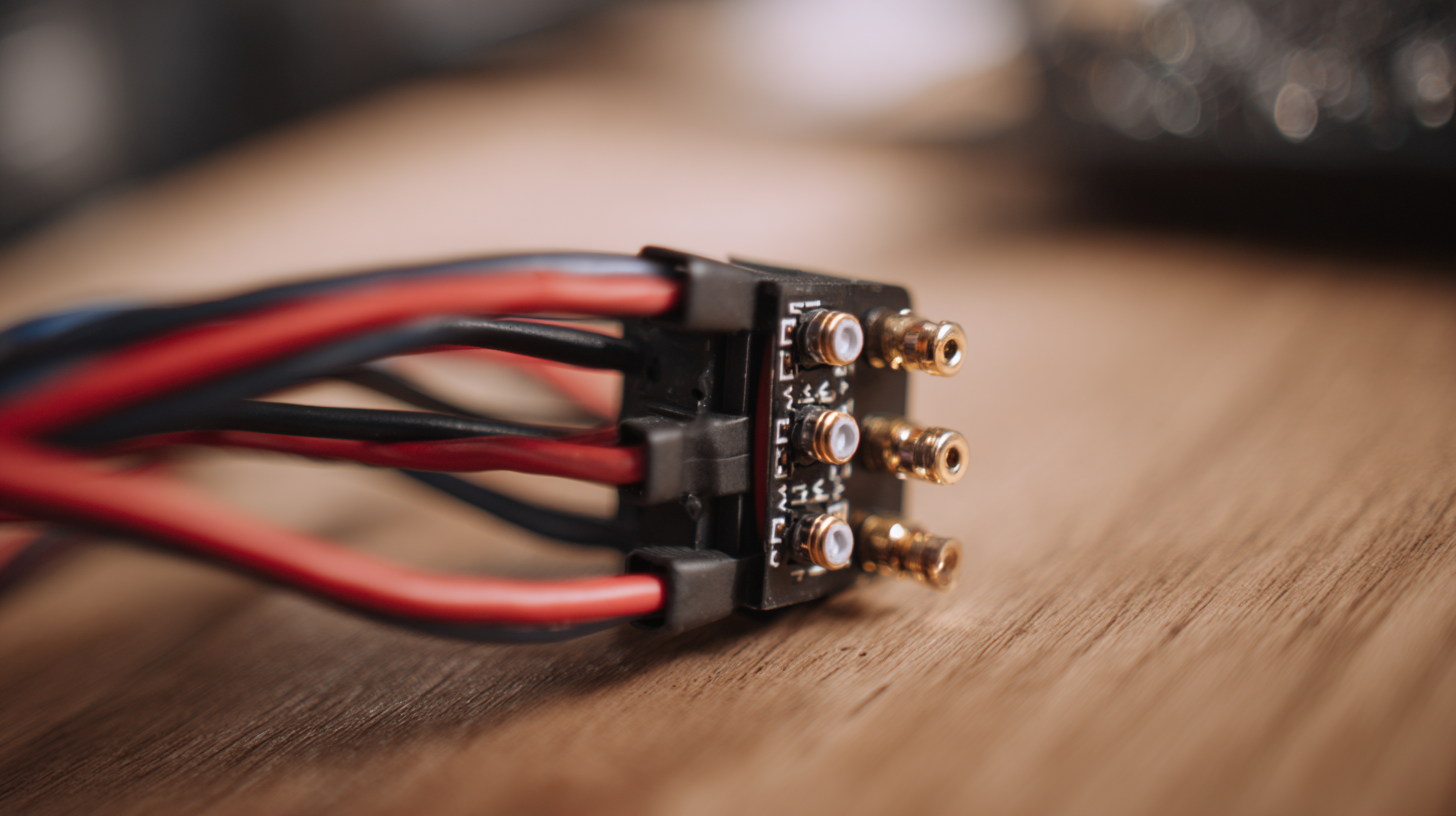

Wired connectors play a pretty big role when it comes to making sure electrical connections are solid and reliable across all kinds of applications—especially in automotive and electronics stuff. Here at Yueqing Haidie Electric Co., Ltd., we’re all about providing top-notch wire harness solutions that are tailored to what our customers actually need. If you’re getting into this field, it’s super helpful to understand the different types of wired connectors out there. From simple spade connectors to more complex multi-pin ones, each kind has its own unique purpose, making sure that power and signals flow smoothly inside your devices.

When you’re choosing connectors, here’s what I’d suggest: First off, match the connector type to what you actually need for your project. For example, if vibrations are a concern, go for locking connectors—they’re way more secure. Second, check the wire gauge compatibility so you don’t end up with issues like overheating or poor performance. And finally, make sure the connectors are made of good-quality materials—especially if they’ll be exposed to stuff like moisture or really hot or cold temperatures.

Getting a handle on the different types of wired connectors and knowing how they’re used can really give beginners the confidence to put together reliable wire harnesses that make their automotive and electronics projects run better. And at Yueqing Haidie Electric, we’re here to support you with the best solutions for your wiring needs—because we get it, good wiring makes a big difference.

Types of Wired Connectors Used in Networking

Essential Tools Needed for Wiring Projects

If you're diving into wiring projects, having the right tools really makes a difference—not just for safety, but also to get things done efficiently. For those just starting out, it’s a good idea to put together a basic toolkit tailored to your needs. Usually, that includes wire strippers, crimping tools, and a multimeter. Wire strippers are super handy because they let you safely take off insulation without messing up the wire's core, which is key for making clean, solid connections. Then there are crimping tools, which are perfect for attaching connectors securely — a big help in keeping your connections sturdy and reliable as you go along.

Oh, and don’t forget about a multimeter! It’s kind of like your troubleshooting buddy — you can use it to check voltage, measure current, or test resistance. Basically, it makes finding and fixing issues a lot easier. If you wanna take things up a notch, a decent soldering iron is a smart investment too. Sometimes, soldering gives you a stronger connection than crimping, especially in certain situations. So, with these tools in your kit, you'll be all set to handle a variety of wiring projects without too much hassle — just remember to stay safe and take your time. Happy wiring!

Step-by-Step Instructions for Making Wired Connections

Getting into wired connections might seem a bit intimidating at first — I get it. But honestly, once you get the hang of it, it’s not so bad. Just start by gathering your gear: a good pair of wire strippers, a crimping tool, and whatever connectors you need. It helps to get familiar with the specific type you’re working with — whether it’s RJ45 for Ethernet cables or RCA for audio. Each one’s a little different, so checking out the manufacturer’s instructions can save you a lot of hassle.

When you’ve got everything ready, here’s a simple way to go about it. First, carefully strip the insulation off the ends of your wires — don’t yank too hard or you might damage the metal inside. Then, lay out the wires in the correct color order for your connector. For Ethernet cables, there’s a specific sequence you’ll want to follow pretty precisely. Once they’re in the right order, carefully insert the wires into the connector all the way to the back.

Now, grab your crimping tool and give it a good squeeze to lock everything in place. It’s smart to give the wire a gentle tug afterward to make sure it’s secure — better to double-check than deal with loose connections later. Once you practice a bit, this whole process becomes much easier, and before you know it, you’ll be confidently handling all sorts of wired setups without breaking a sweat.

Common Mistakes to Avoid When Using Wired Connectors

When you're just starting out with wired connectors, it's pretty common to overlook some important details that can lead to mistakes—and even safety issues. A lot of beginners end up wiring things incorrectly, which can stop devices from getting the power they need. In fact, more than half of the initial problems people face with electrical setups are due to these wiring blunders. Making sure your connections are spot-on is actually super important to avoid things like inefficiency or, worse, fires caused by bad wiring.

To steer clear of these typical wiring mistakes, always double-check that your connectors are compatible before you jump in. That means making sure the wire gauge lines up with what your devices call for—and that all the connections are tight and secure. Also, avoid using old or worn-out appliances because they dramatically raise the risk of electrical fires. And be careful not to overload outlets; spreading out the load helps prevent overheating and failures.

On the safety side of things, never try to reuse old appliance cords for new projects—they're just not made for that and can be pretty dangerous. Keep an eye out for faulty outlets or low-hanging cables that could cause accidents, and make it a habit to check your space regularly. Follow these simple tips, and you'll have a safer, more reliable wiring setup—keeping everything running smoothly for you and your devices.

Safety Tips and Best Practices for Wired Connector Use

When you're working with wired connectors, safety should always come first—no exceptions.

Honestly, no matter how experienced you are, knowing the best practices can make a huge difference in preventing accidents and making sure everything stays reliable.

Start by giving your connectors a good look over—check for any signs of wear, cracks, or damage. Using damaged parts is just asking for trouble, like connection failures or worse.

And a quick tip: always disconnect the power before you mess with the wiring.

It’s a no-brainer, but it’s so important to avoid shocks or short circuits.

Wearing insulated gloves and grabbing tools with rubber handles isn’t a bad idea either—they really boost your safety game.

When you're working with wired connectors, safety should always come first—no exceptions.

Honestly, no matter how experienced you are, knowing the best practices can make a huge difference in preventing accidents and making sure everything stays reliable.

Start by giving your connectors a good look over—check for any signs of wear, cracks, or damage. Using damaged parts is just asking for trouble, like connection failures or worse.

And a quick tip: always disconnect the power before you mess with the wiring.

It’s a no-brainer, but it’s so important to avoid shocks or short circuits.

Wearing insulated gloves and grabbing tools with rubber handles isn’t a bad idea either—they really boost your safety game.

At Yueqing Haidie Electric Co., Ltd., we pride ourselves on offering top-notch wire harness solutions, especially for the automotive industry. Our team’s expertise means you get connectors that don’t just meet standards—they often go beyond. When you’re installing or maintaining those wired connectors, make sure to follow the manufacturer’s instructions carefully. Proper crimping and soldering are key to making strong, reliable electrical connections. Keep these safety tips and best practices in mind, and you’ll improve your wiring’s dependability—keeping your projects safe and protecting the end users who rely on your work.

Exploring the Versatility and Benefits of the PIN HD026-2-11E Male Unsealed Automotive Wire Harness Connector

When it comes to automotive electrical systems, the reliability and versatility of connectors play a crucial role in vehicle performance and safety. The PIN HD026-2-11E Male Unsealed Automotive Wire Harness Connector exemplifies quality engineering that meets the demanding requirements of vehicle manufacturers. This connector not only ensures secure connections but also accommodates diverse applications due to its robust design. According to a report from the Automotive Component Manufacturers Association (ACMA), reliable connectors are essential for minimizing electrical failures, which account for approximately 30% of automotive breakdowns.

The HD026-2-11E connector features a 2-pin configuration that is extremely efficient for various automotive wiring needs. It works seamlessly with the 2pin Auto Connecting Crimp Type Stamping Female Wire Crimp Terminal, making installation straightforward and sturdy. Studies indicate that connectors with crimped terminals, like the HD026 series, show superior performance in terms of electrical conductivity and longevity compared to soldered connections. This makes them ideal for high-vibration environments often encountered in automotive applications.

Moreover, the unsealed design of the HD026-2-11E connector allows for adaptability in different settings, though it's essential to consider environmental factors when choosing a connector. Reports indicate that over 50% of electrical issues in vehicles stem from inadequate protection against moisture and dust. While the HD026 connector is adaptable, automotive manufacturers often recommend pairing it with appropriate sealing and protective measures to enhance durability. Such practices significantly increase the lifespan and reliability of automotive electrical systems, making the HD026 series a preferred choice in today's evolving automotive landscape.

FAQS

: Wired connectors are components that facilitate the transmission of electrical signals and power, serving as the link between cables and devices in electronic setups.

Common types of wired connectors include USB connectors, HDMI connectors, and Ethernet jacks, each designed for specific functionalities.

USB connectors are widely used to charge electronics and transfer data between devices, making them essential in today's technology.

HDMI connectors are important for transmitting high-definition video and audio signals between devices, such as TVs and computers.

Essential tools for wiring projects include wire strippers, crimping tools, a multimeter, and optionally, a soldering iron for stronger connections.

Wire strippers are important because they safely remove insulation from wires without damaging the conductive core, ensuring clean and effective connections.

A crimping tool is used to securely attach connectors to wires, ensuring that the connections remain robust and reliable throughout the project.

A multimeter is invaluable for troubleshooting and testing circuit continuity, as it measures voltage, current, and resistance to help diagnose electrical issues.

A soldering iron can provide stronger connections than crimping in certain applications, enhancing the durability and reliability of wiring projects.

Conclusion

In

Related Posts

-

Comprehensive Guide to Best Wire Connecters with Technical Specifications and Installation Tips

-

Unveiling Top Examples of the Best Wire Connector Harness for Your Projects

-

Exploring Unique Alternatives to Best Automotive Crimp Connectors for Your Projects

-

How to Choose the Right VW Connector for Your Automotive Needs

-

The Definitive Guide to Choosing the Best Automotive Circuit Connectors for Maximum Performance

-

2025 Automotive Connector Trends: An In-Depth Comparison of the Best Connectors in Car Technology

Blog Tags: