Ultimate Guide to Choosing the Best Vehicle Wiring Connectors for Your Needs

Table of Contents

- Understanding Vehicle Wiring Connectors: Types and Their Applications

- Key Factors to Consider When Selecting Wiring Connectors for Vehicles

- Industry Standards: Importance of Certifications in Wiring Connector Manufacturing

- Comparative Analysis of Wiring Connector Materials: Durability and Performance

- The Role of Environmental Testing in Ensuring Connector Reliability

- Market Trends: Emerging Technologies in Vehicle Wiring Connectors and Their Impact

- Enhancing Automotive Reliability: Insights from 2023's Electrical Connector Market Trends & the 14P Auto Waterproof Connectors

- FAQS

- Related Posts

As the automotive world keeps evolving, you really can't overlook how crucial reliable vehicle wiring connectors are. I mean, market research shows that the global automotive wiring harness market is expected to hit around $70 billion by 2025. That’s mainly because there's such a rising demand for cool new vehicle tech and electric cars these days. Here at Yueqing Haidie Electric Co., Ltd., we totally get how vital these connectors are for keeping all the electrical parts in modern cars talking to each other smoothly. We’re all about providing top-notch wire harness solutions that fit the different needs of our customers in the auto parts game. Thanks to our easy access to transportation and a real passion for quality, we’ve earned a pretty solid reputation. We’re proud to help new brands get started and emphasize just how important it is to pick the right vehicle wiring connectors—because that’s what keeps performance running smoothly and safety intact.

Understanding Vehicle Wiring Connectors: Types and Their Applications

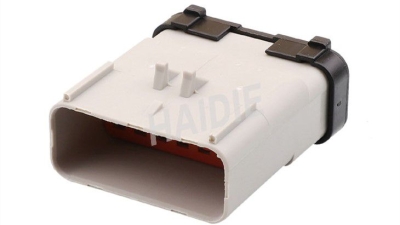

When you’re dealing with vehicle wiring connectors, having a good grasp of the different types and what they’re used for is super important if you want to make smart choices. I came across a recent report from MarketsandMarkets that says the global market for automotive connectors is expected to hit around $28.3 billion by 2025. A big reason for this growth is the rising demand for more advanced electrical systems in cars these days. Now, within all the connector types, you’ve got wire-to-wire, wire-to-board, and board-to-board connectors, and each plays its own unique role in the automotive world. For example, wire-to-wire connectors are pretty much what you need when connecting two wires—these give car designs a lot of flexibility. On the other hand, wire-to-board connectors are great for linking wires to printed circuit boards, making everything more organized and efficient.

Each kind of connector is suited for different situations, depending on things like wire thickness, current needs, and the environment it’s used in. Sealed connectors, for instance, are made to handle exposure to moisture, dirt, and rough conditions—perfect for off-road vehicles or tough environments. It turns out that more than half of vehicle manufacturers are now leaning toward using these sealed connectors to keep everything reliable under harsh conditions.

And with electric vehicles becoming more popular, there’s also going to be a big push for connectors that can handle higher voltages and greater power loads. So, understanding all this isn’t just about picking the right connector—it’s really about making sure the vehicle’s electrical system is safe, durable, and up to date.

Key Factors to Consider When Selecting Wiring Connectors for Vehicles

When you're picking wiring connectors for your vehicle, there are a few important things you should keep in mind to make sure everything works smoothly and stays reliable. First off, compatibility is key—make sure you choose connectors that match your vehicle's existing wiring. That means paying attention to the wire gauge and finding the right type of connector that fits your specific setup. It's also worth thinking about where the connectors will be used—will they be exposed to moisture, heat, or vibrations? If so, go for ones that are built tough enough to handle those tough conditions over time.

Another thing not to overlook is what the connectors are made of. Look for high-quality materials like corrosion-resistant metals or sturdy plastics—that way, they'll hold up well in the harsh environments inside a car. You should also check the rated current and voltage to be sure they can handle your electrical loads without overheating. And hey, let's not forget about how easy they are to install—simplicity can save you a lot of time and frustration. Picking connectors that are straightforward to work with and come with clear instructions really makes the whole wiring process a lot less of a headache.

Vehicle Wiring Connectors Selection Factors

Industry Standards: Importance of Certifications in Wiring Connector Manufacturing

So, when it comes to picking the right wiring connectors for your car, it’s pretty important—not just for performance, but also for safety. One thing people often overlook is checking for industry certifications. Honestly, certified connectors are a bit like the VIP pass—they’ve been tested to meet tough quality standards, so they can handle harsh conditions like extreme heat, cold, or moisture without failing. Skimping on this can really cost you later on with expensive repairs or even worse issues.

When you’re shopping around, it’s a good idea to look for certifications from legit bodies like ISO, SAE, or UL. These labels tell you that the connectors have gone through serious testing and are built to perform. And don’t forget—if you see ones specifically rated for automotive use, that’s even better. They’ll be more reliable and suited for your vehicle.

**Pro tip:** Before pulling out your wallet, take a minute to review the product specs. Make sure the connector’s certifications line up with industry standards, and check what materials and design they use. Picking a connector with the right certifications not only keeps things safe but also helps your wiring last longer in the long run.

Ultimate Guide to Choosing the Best Vehicle Wiring Connectors for Your Needs - Industry Standards: Importance of Certifications in Wiring Connector Manufacturing

| Connector Type | Application | Certification Standards | Temperature Range | Max Current Rating |

|---|---|---|---|---|

| Sealed Connectors | Automotive | IP67, SAE J2030 | -40°C to 125°C | 20A |

| Terminal Blocks | Industrial Applications | UL 1059 | -10°C to 90°C | 15A |

| Anderson Connectors | Battery Connections | IEC 60320, UL 1977 | -40°C to 105°C | 120A |

| Molex Connectors | Consumer Electronics | UL 1977, RoHS Compliant | -40°C to 85°C | 5A |

| Weather-Pack Connectors | Automotive | SAE J2030 | -40°C to 125°C | 30A |

Comparative Analysis of Wiring Connector Materials: Durability and Performance

When you're choosing wiring connectors for a vehicle, the materials used can really make a big difference in how long they last and how well they perform. Usually, you'll find materials like copper, aluminum, and different types of plastics. Copper connectors are pretty popular because they conduct electricity so well, making them perfect for high-performance setups. On the other hand, if you're dealing with tough environments—think marine conditions or off-road adventures—materials like aluminum with protective coatings tend to hold up better over time without losing their performance.

And it's not just about the metal parts; the insulative materials matter too. Thermoplastics are flexible and easy to shape, but they might not handle extreme heat as well as thermosets, which are more rigid and can stand up to high temperatures. Picking the right material really depends on what you need, and it can be the difference between a connection that keeps working and one that fails at the worst possible time. As cars and trucks get more tech-heavy, understanding these material choices is super important if you want to make smart decisions when selecting connectors.

The Role of Environmental Testing in Ensuring Connector Reliability

You know, environmental testing really plays a huge role when it comes to making sure vehicle wiring connectors are reliable. In the auto world, where nothing short of durability cuts it, these connectors often face some pretty tough conditions—think temperature swings, humidity, and even exposure to things that can cause corrosion.

According to a report from the IEC, connectors that go through thorough environmental testing can see their failure rates drop by up to 40%. That’s pretty significant, especially for cars, because if a connector fails, it can seriously mess with vehicle performance.

On top of that, the kind of materials and coatings we use in connector design is heavily influenced by how well they hold up in these tests. For example, connectors with IP67 weatherproof ratings are built to resist water and dust intrusion, which really helps them last longer out in the field. SAE International did a study showing that about 60% of connector failures in vehicles are actually related to environmental factors.

So, investing in properly tested connectors isn’t just about ticking some box for compliance—it’s a smart move that boosts overall reliability and safety. Bottom line? It leads to happier customers who trust the brand and feel confident in their vehicles.

Market Trends: Emerging Technologies in Vehicle Wiring Connectors and Their Impact

Hey, if you look at the vehicle wiring connectors market these days, it’s really going through some major changes. Thanks to new tech and shifting market trends, things are moving fast. For instance, with more electric and hybrid cars on the road, there’s a big push for better, more reliable wiring solutions. Industry reports say the automotive PCB market, for example, is expected to jump from about $9.15 billion in 2023 to roughly $15.1 billion by 2032, growing at around 5.9% annually. That clearly shows how much we're relying on smarter electronic systems in vehicles now, which obviously means we need more advanced wiring connectors.

On top of that, as the car industry leans more and more towards electrification, the HVAC market in India is also booming. Predictions say it could hit around $15.42 billion by 2024, and it’s just gonna keep expanding since folks are now more into energy-efficient rides that support eco-friendly practices. Plus, with electric and hybrid vehicles becoming more popular, there’s a rising need for high-performance wiring connectors that can handle the unique challenges these new techs throw at them. As automotive tech keeps evolving, using next-gen wiring solutions will be key—not just for manufacturers, but for consumers too, making sure everything runs smoothly and safely.

Enhancing Automotive Reliability: Insights from 2023's Electrical Connector Market Trends & the 14P Auto Waterproof Connectors

The automotive industry is rapidly evolving, and one of the crucial elements in enhancing reliability is the advancement of electrical connectors. In 2023, trends within the electrical connector market highlight a significant shift towards waterproof solutions, exemplified by the growing demand for 14P Auto Waterproof Connectors. These connectors are designed to withstand harsh environmental conditions, ensuring seamless performance and safety in vehicles. Their robust design not only protects against moisture infiltration but also minimizes the risk of electrical failures, which can lead to costly repairs and compromised vehicle performance.

With the shift towards electric vehicles and increased reliance on advanced electronic systems, the need for high-quality, reliable connectors has never been more critical. The 14P Auto Waterproof Connectors stand out by offering superior durability and versatility, making them ideal for various applications, from battery management systems to infotainment setups. As automotive manufacturers prioritize reliability, investing in such innovative solutions will play a pivotal role in optimizing vehicle performance and longevity, responding to the market's call for enhanced safety and dependability.

FAQS

: The main types of vehicle wiring connectors include wire-to-wire, wire-to-board, and board-to-board connectors, each serving specific roles in the automotive sector.

Sealed connectors are designed to withstand moisture and dirt, making them ideal for off-road vehicles and ensuring durability and reliability in harsh conditions.

Common materials include copper, aluminum, and various plastics, with copper offering excellent conductivity and aluminum providing enhanced durability in corrosive environments.

Thermoplastics are flexible and easy to mold but may lack heat resistance, whereas thermosets are more rigid and durable under extreme temperatures.

Over 50% of vehicle manufacturers prioritize the use of environmentally sealed connectors to enhance the durability and reliability of wiring systems.

The global automotive connector market is projected to reach $28.3 billion by 2025, fueled by the increasing demand for advanced electrical systems, especially in electric and hybrid vehicles.

Emerging technologies drive the development of more efficient and reliable wiring solutions, especially in light of the growing reliance on sophisticated electronic systems in vehicles.

The choice of connector materials significantly affects durability and performance, making it essential to select appropriate materials for specific applications to avoid costly failures.

The automotive PCB market is expected to grow from $9.15 billion in 2023 to $15.1 billion by 2032, indicating a strong trend toward more advanced electronic systems in vehicles.

High-performance wiring connectors are crucial in electric vehicles as they must accommodate increased power demands and higher voltages, ensuring reliable and efficient operation.

Related Posts

-

How to Choose the Best Connector Housing for Your Global Sourcing Needs

-

The Ultimate Guide to Sourcing the Best Automotive Electrical Terminals for Optimal Vehicle Performance

-

7 Essential Tips for Choosing the Best Car Cable Connectors for Your Vehicle

-

7 Proven Benefits of Choosing the Best Connector Housing for Your Needs

-

Navigating the Future Market of Hirschmann Connectors by 2025 with Expert Insights and Practical Steps

-

Unleashing the Power of China's Manufacturing with Best Car Wire Plug Innovation

Blog Tags: