What are Wire Harness Terminal Connectors and Their Key Applications?

Table of Contents

- Understanding Wire Harness Terminal Connectors: A Comprehensive Overview

- Types of Wire Harness Terminal Connectors and Their Functions

- The Importance of Wiring Harnesses in Electrical Systems

- Key Applications of Wire Harness Terminal Connectors in Various Industries

- Best Practices for Choosing and Installing Wire Harness Terminal Connectors

- Troubleshooting Common Issues with Wire Harness Terminal Connectors

- Enhance Your Vehicle's Performance with 185026-1 Automotive Brass Electrical Battery Connectors: A Comprehensive Guide

- FAQS

- Conclusion

- Related Posts

You know, in today’s fast-paced auto industry, you can’t underestimate how important reliable electrical connections really are. Those wire harness terminal connectors? They’re pretty much the backbone of making sure all the electrical signals in a vehicle flow smoothly — and that’s a big deal when it comes to performance and safety. Interestingly, recent reports show that the global market for automotive wire harnesses is expected to hit around $63.5 billion by 2027. That’s pretty impressive growth, driven by more cars being made and the increasing need for sophisticated electrical systems in vehicles. Over at Yueqing Haidie Electric Co., Ltd., we really focus on providing top-notch wire harness solutions, especially for auto parts. Our dedication to quality has earned us a lot of praise, and it’s even helped us develop some derivative brands. As we dive into the ways wire harness terminal connectors are used, we want to emphasize just how vital these little components are to modern car design and functionality — they’re honestly a game-changer.

Understanding Wire Harness Terminal Connectors: A Comprehensive Overview

Wire harness terminal connectors are pretty important when it comes to making sure electrical signals get where they need to go. Basically, these connectors act as key junction points within the wiring systems, helping to keep connections between different parts secure and reliable. You'll find them everywhere—think automotive, aerospace, industrial machinery—you name it. If you're into designing or maintaining electronic setups, it’s good to understand how they’re built and how they work.

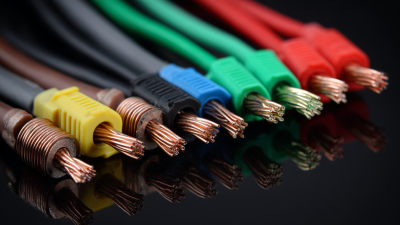

At their core, these connectors are made up of metal terminals that get crimped onto wires, all tucked inside a protective insulating shell. This setup not only keeps things safe from environmental elements but also helps prevent accidental disconnections. They come in various shapes and sizes, so you can use different wire gauges depending on your project, which makes them super versatile. Plus, they make assembly smoother and boost safety—which is a total win in modern electrical work where efficiency and dependability really matter.

You’ll see these connectors used pretty much everywhere. In cars, for example, they link power to stuff like the ignition, lights, and sensors. In aerospace, they’re crucial for keeping communication lines running smoothly in the avionics systems—ensuring everything works safely and without hiccups. As tech keeps evolving, the need for sturdy, efficient wire harness connectors is only going to grow. No doubt, they’re a pretty essential part of today’s electronic design and installation world.

Types of Wire Harness Terminal Connectors and Their Functions

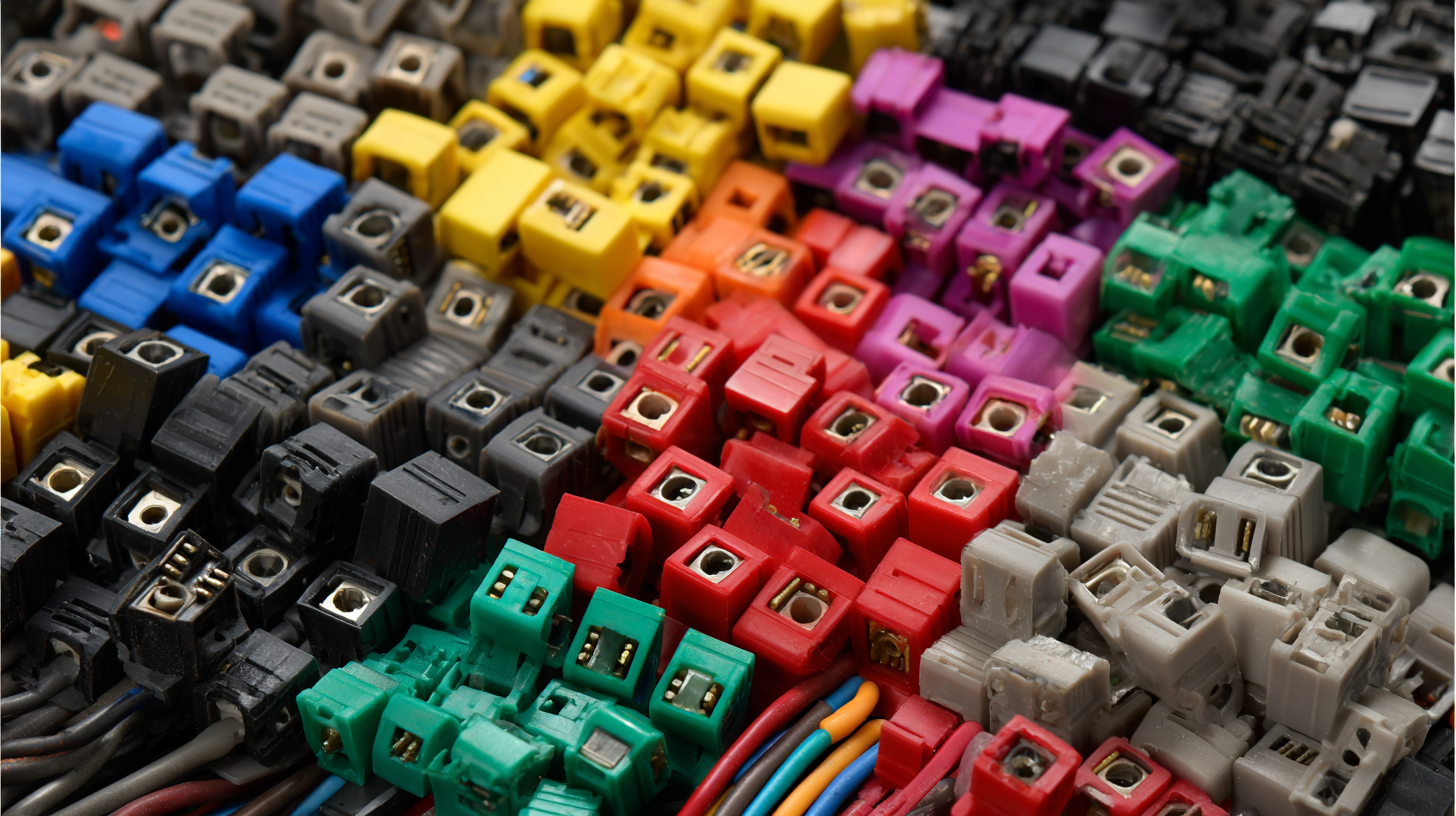

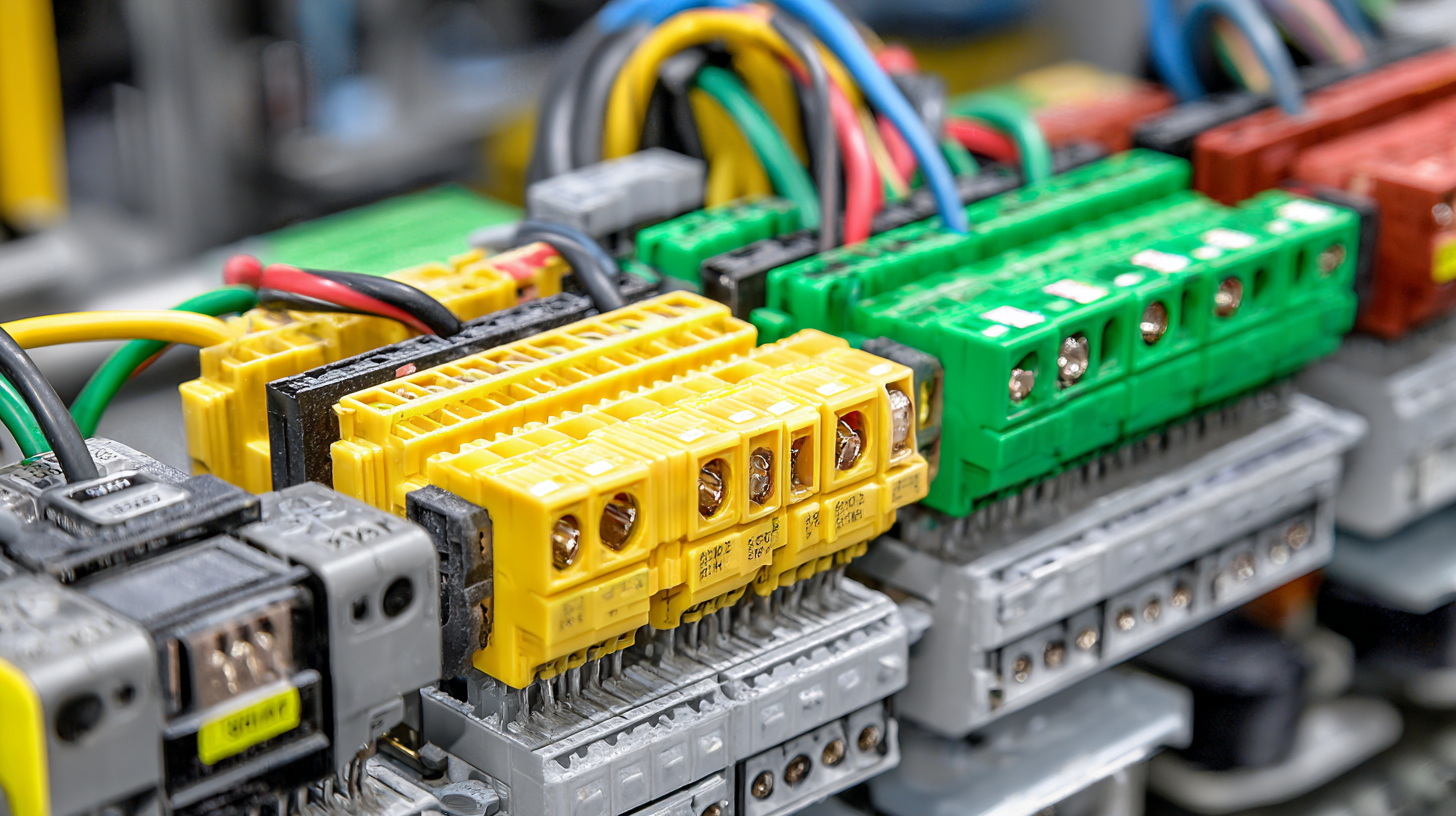

Wire harness terminal connectors are pretty essential in a bunch of different applications, especially in cars. They basically make sure electrical signals get from one place to another smoothly through the wiring, so everything runs just right. There are a few types of these connectors, like terminal blocks, spade connectors, and bullet connectors, each with their own special purpose. For instance, terminal blocks let you connect multiple wires in a small space, spade connectors are super handy if you want to disconnect quickly for repairs or maintenance, and bullet connectors are great in places where there's a lot of vibration — they tend to stay put reliably.

Looking ahead, the global market for electric vehicle connectors is expected to grow a lot — it might hit around $8.8 billion by 2032. That just highlights how important good-quality wire harness designs are becoming. Companies like Yueqing Haidie Electric Co., Ltd. are really stepping up to meet this demand, focusing on creating reliable, efficient automotive parts. They’re not just about performance — quality, safety, and durability are a big deal. All in all, it’s clear that strong wire harness solutions are a cornerstone of modern, safe, and long-lasting vehicles.

Wire Harness Terminal Connectors: Types and Applications

This bar chart illustrates the market share of different applications of wire harness terminal connectors. The automotive industry holds the largest market share at 30%, followed by industrial applications at 25%. Aerospace, consumer electronics, and telecommunications sectors also play significant roles in the wire harness connector market.

The Importance of Wiring Harnesses in Electrical Systems

Wiring harnesses are pretty essential when it comes to making sure electrical systems work smoothly and reliably, no matter the industry. Basically, they’re these organized bundles of wires, connectors, and terminals that help keep all the electrical components connected neatly and efficiently. The way they’re built makes installation a lot easier and keeps everything tidy — plus, it helps cut down on electrical noise or damage. As systems get more complicated, having a solid wiring harness becomes even more critical to ensure signals move correctly and safely.

You see these harnesses everywhere—from cars and airplanes to your favorite gadgets. For example, in a car, they connect key parts like sensors, lights, and power sources. When designed well, they can reduce the chance of shorts and stand up better to tough environmental conditions. Plus, with new materials and smarter manufacturing, harnesses are now lighter, smaller, and just as reliable. As tech keeps advancing, it’s clear that high-quality wiring harnesses will keep playing a huge role in building safe and innovative electrical systems.

Key Applications of Wire Harness Terminal Connectors in Various Industries

Wire harness terminal connectors are pretty important across different industries—they’re crucial for making sure electrical connections stay reliable and efficient. Take the automotive world, for example; as vehicles become more sophisticated with all their electronic gadgets, these connectors become even more essential. I recently read that the global market for automotive wiring harnesses is expected to hit around $70 billion by 2027. A big part of this growth is fueled by the rise in electric vehicles and all the new driver-assistance tech popping up everywhere.

Over in telecommunications, those wire harness terminal connectors are the unsung heroes behind lightning-fast data transfer and solid signal quality. With 5G rolling out, the need for quick and dependable communication networks has skyrocketed, so you see more of these connectors being used in everything from network setups to your personal devices. According to Market Research Future, the telecom wiring harness market is projected to grow at an annual rate of around 8% from 2021 through 2028, which shows just how vital these little components are for keeping up with our modern tech demands.

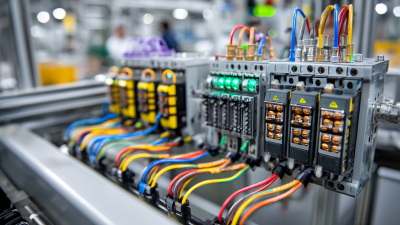

And let's not forget industrial automation—these connectors are a big deal there too. They help boost productivity and keep things safe on the factory floor. As industries jump onto IoT and smart manufacturing bandwagons, the need for strong, durable connectors has really taken off. Allied Market Research predicts that the market for industrial automation connectors will reach about $16 billion by 2025. It’s pretty clear—wire harnesses play a key role in connecting all the automated machinery working behind the scenes to keep everything running smoothly.

Best Practices for Choosing and Installing Wire Harness Terminal Connectors

When you're picking out wire harness terminal connectors, it's super important to keep a few best practices in mind to make sure everything works smoothly and lasts a long time. First off, think about what the application actually needs—like how much current it’s going to carry, the environmental conditions (think moisture, heat, etc.), and what kind of wire you’re using. These things will really help you decide on the right connector—whether you want a locking one for extra security or a sealed option to keep out moisture.

Another big tip? Always double-check that your connectors are compatible with both the wires and the devices you're hooking up. Using mismatched parts can lead to flaky connections or even damage, and trust me, that can get pretty expensive to fix. When you're installing, make sure to strip the wires correctly and crimp them well. That way, you get a solid, reliable connection and avoid issues down the road like loose wiring that could cause trouble.

And don’t forget to protect those connections! Using heat shrink tubing or some cable ties can go a long way in defending against things like water or physical stress. Paying attention to these small details might seem minor, but they can really boost the performance and lifespan of your wire harness connectors, no matter what project you're tackling.

Troubleshooting Common Issues with Wire Harness Terminal Connectors

When dealing with wire harness terminal connectors, troubleshooting those little issues can really make a difference in how well they perform and how reliable they are. One of the most common hiccups is poor connection — usually caused by corrosion or dirt buildup on the terminals. It's a good idea to regularly inspect and give them a cleanup; contact cleaners can do wonders in removing dirt and restoring that solid, reliable contact. Also, making sure the terminals are crimped properly is crucial — a good crimp guarantees a tight mechanical and electrical connection, so you're less likely to face circuit interruptions.

On top of that, another thing folks often run into is inserting or disconnecting the terminals the wrong way. Misalignment can cause connections to be flaky, which is especially problematic in critical systems like cars or even aerospace stuff. Using guides or fixtures during assembly can really help keep things on point. Plus, training your technicians on proper handling techniques goes a long way — it helps prevent damage to the connectors and makes them last longer, saving money in the long run. Overall, staying ahead of these common issues can really boost the performance and lifespan of your wire harness terminals. It’s all about a bit of preventive care and making sure everything’s done right from the get-go.

Enhance Your Vehicle's Performance with 185026-1 Automotive Brass Electrical Battery Connectors: A Comprehensive Guide

When it comes to enhancing your vehicle's performance, one often-overlooked component is the battery connector. The 185026-1 Automotive Brass Electrical Battery Connectors are designed to improve connectivity and efficiency in your vehicle’s electrical system. These terminals are essential for ensuring a stable connection between your battery and the various electrical components of your vehicle, which can significantly impact overall performance.

Research indicates that poor battery connections can lead to electrical failures, system malfunctions, and decreased fuel efficiency. A study conducted by the Automotive Industry Association found that nearly 30% of vehicle electrical issues stem from faulty connectors and terminals. By opting for high-quality connectors like the 185026-1, drivers can mitigate these risks and ensure optimal power distribution, which is crucial for the reliable operation of advanced vehicle systems.

Made from durable brass, the 185026-1 connectors are not only resistant to corrosion but also offer superior conductivity compared to traditional aluminum connectors. This translates into lower resistance and heat generation during operation, further enhancing vehicle performance. In fact, industry experts suggest that using premium battery terminals can improve the overall lifespan of the vehicle’s electrical system by as much as 20%. Investing in quality products like the 185026-1 Automotive Brass Electrical Battery Connectors is a smart move for any vehicle owner aiming for reliability and extended vehicle performance.

FAQS

: Wire harness terminal connectors are components that secure and ensure the reliable connection between different elements in various systems, such as automotive and aerospace, by facilitating efficient transmission of electrical signals.

They consist of metal terminals that are crimped onto wires and housed within a protective insulating shell, safeguarding against environmental factors and preventing accidental disconnections.

Key industries include automotive, aerospace, telecommunications, and industrial automation, where reliable electrical connections are crucial.

In automotive settings, they connect power to critical systems such as ignition, lights, and sensors, particularly as vehicle electronic systems become more complex.

The automotive wiring harness market is projected to grow significantly, reaching $70 billion by 2027, primarily driven by the rise in electric vehicle production and advanced driver-assistance systems.

They are essential for facilitating high-speed data transfer and maintaining signal integrity, particularly with the growth of 5G technology.

The telecommunications wiring harness market is anticipated to grow at a CAGR of over 8% from 2021 to 2028 due to the increased demand for reliable communication networks.

They enhance productivity and ensure safety in manufacturing processes, playing a vital role in connecting various automated systems as industries adopt IoT solutions.

The industrial automation connectors market is expected to reach $16 billion by 2025, highlighting the importance of wire harnesses in modern manufacturing techniques.

Factors include advancements in technology, the surge in electric vehicle production, the rollout of 5G networks, and the adoption of smart manufacturing techniques.

Conclusion

Wire harness terminal connectors are pretty much the backbone when it comes to keeping electrical systems running smoothly across different industries. They help create secure, reliable connections inside wire harnesses, making sure the electrical current flows just right. Honestly, understanding the various types of these connectors and what they do is key — it really helps you pick the right ones for any project.

Here at Yueqing Haidie Electric Co., Ltd., we’re all about providing top-notch wire harness solutions, especially for the automotive world. Over the years, our focus on quality and expertise in wire harness terminal connectors has earned us a lot of good feedback from our customers. We’re dedicated to following best practices — whether it’s choosing the right connectors, properly installing them, or tackling common troubleshooting issues — all to make sure your electrical systems perform at their best.

Related Posts

-

Comprehensive Guide to Best Wire Connecters with Technical Specifications and Installation Tips

-

Unleashing the Power of China's Manufacturing with Best Car Wire Plug Innovation

-

Ultimate Guide to Choosing the Best Wire Harness Connectors and Terminals for Optimal Performance

-

2025 Automotive Connector Trends: An In-Depth Comparison of the Best Connectors in Car Technology

-

The Future of Innovation in Harness Connectors for Smart Technology

-

5 Reasons Why Board To Wire Connections Drive 30 Percent More Efficiency in Industrial Applications

Blog Tags: